Versarien PLC Chief Executive Officer Neill Ricketts caught up with DirectorsTalk for an exclusive interview to discuss their Cambridge Graphene RNS, the progress of scaling up the graphene manufacturing capabilities and what it means to have the equipment already in place

Q1: Neill, we saw an update earlier on your Cambridge operations, can you remind of the details and the rationale behind the acquisition of Cambridge Graphene?

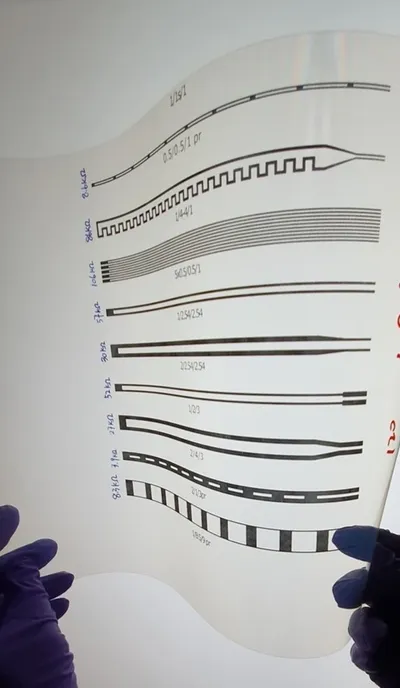

A1: Sure, so things are moving very quickly for us, we announced that we’ve acquired a majority stake in Cambridge Graphene, which is a spin-out for the University of Cambridge, a couple of weeks ago. On the back of that, we had an over-subscribed placing in order to get the capital equipment required to really start to take that technology and to develop it at the University. The reason that we’re really interested in that is that they have a different type of graphene that they produce there from the graphene we produce as a result of our own patented process, the 2 processes work very closely together and in fact they operate in completely difference areas which enables us to cover all of the graphene market. The material that’s produced at the University of Cambridge is an ink and will be used in things like printable electronics and RFID tags, technologies of the future, that will enable us to really know what’s happening in our environment. So, it’s really important for us to really get going on that, we’ve got some really good enquiries and now we’re building up our capacity.

Q2: At the time of your fundraising, earlier this month, you said that you’d be using the proceeds to significantly scale up both graphene manufacturing capabilities and marketing efforts and to take advantage of the substantial commercial opportunities that you’d seen. How are you progressing with this?

A2: So, as Versarien were able to announce this morning, we’ve established a base now at the University of Cambridge, we’ve now got the kit ordered and actually commissioned in a period of about 10 days, which I think is simply staggering from our team and they’ve already sold their first order out of that facility down in Cambridge to a company looking for some graphene ink. In terms of the Nanene and the new materials we announced just a couple of months ago, I’ve just come out of a marketing meeting where we are managing expectations with some very very large customers at a very early stage in order to facilitate getting that technology really moving as well. We haven’t actually ordered the equipment for that yet until we can establish that we’ve got significant demand but it’s all ready to go and we’ll looking forward to placing all that equipment on order. We’re a relatively small team so at the moment we’ve concentrated on getting Cambridge up and running, getting it to the same sort of levels that we’ve got down in Cheltenham and then it’s all go on the Cheltenham facility.

Q3: What does it mean having the equipment in place already, what does that mean for Versarien PLC?

A3: So, we’ve got an established production base down here in Cheltenham, where I am today, and the guys are downstairs making material for the guys to sell we were just talking about in this meeting and that means that we’re up and ready, we’re able to satisfy the demands of our customers. We’ve just expanded on that by having this other capability down at the University of Cambridge and over the next couple of weeks we’ve got a very active schedule and we’ve got lots of opportunities for us to display our technology at various technology events. Having the equipment in place means that our customers are able to place orders with confidence that we’re able to supply, in fact one of our investors asked us the other day what would happen if he placed a rather significant order right now and one of our guys in the Cheltenham office said it’s not a problem, we’d be able to supply that straight out of the stock. For customers, it means that there’s a degree of confidence, in being able to place an order with us, to be able to satisfy their needs.