Versarien plc (LON:VRS), the advanced engineering materials group, has announced its unaudited results for the year ended 31 March 2020.

Operational highlights

· Commercial Partnership Agreement with the Company’s textile sector collaboration partner, MAS Innovation (Private) Limited, to develop new garments utilising Versarien’s graphene ink materials

· Awarded €350,000 grant to participate in the Graphene Flagship project, led by Airbus to develop graphene based thermo-electric ice protection systems to prevent icing on aircraft surfaces

· Partnership with Rolls Royce and the University of Manchester’s Graphene Engineering Innovation Centre (“GEIC”) using chemical vapour deposition (“CVD”) in wiring for next generation aerospace engine systems

· Grant of £104,000 from the Advanced Propulsion Centre for the development of low-carbon technologies to significantly reduce vehicle emissions

Financial highlights

· Group revenues of £8.3million (2019: £9.1 million)

· Adjusted LBITDA* of £0.6 million (2019: £1.1 million)**

· Loss before tax of £4.7 million (2019: £2.8 million) after share based payments charge in the year of £1.2 million (2019: £0.7 million)

· Cash at 31 March 2020 of £1.7 million (2019: £4.3 million)

· Successful fundraising of £6 million gross in March 2020 re-invested into the 24-month sharing agreement with Lanstead Capital Investors LP (“Lanstead”),a US headquartered institutional investor, with a currently assessed fair value of £7 million

· Net assets of £15.7 million (2019: £13.3 million)

* Adjusted LBITDA (Loss before interest, tax, depreciation and amortisation) excludes exceptional items and share based payment charges ** IFRS 16,leases, was adopted on 1 April 2019 using the modified retrospective approach and comparatives are therefore not restated under this method. The impact of this adoption has resulted in a reduction in LBITDA of £0.7 million in 2020

Post Period highlights

· Product development agreement signed with J&P Coats Limited, part of Coats Group plc, to incorporate graphene nano-platelets and graphene inks into consumer textiles

· £5 million Innovate UK loan awarded in June 2020, with security arrangements completed, for scale up and product development related to the GSCALE collaborations

· Graphene Enhanced Protective Face Masks launched with first orders received for 120,000 masks.

Commenting, Neill Ricketts, Chief Executive Officer of Versarien, said:

“Recent times have been dominated by the challenges that the Covid-19 pandemic have presented on a global basis. However, I am pleased to report Versarien has continued to operate throughout and achieved much during lockdown.

“I am particularly grateful for the support of the UK Government both in its provision of a £5 million loan via Innovate UK to allow us the opportunity to scale up and to expand the reach of our graphene operations.

“Our global expansion plans have changed direction slightly as we have decided that progressing into the Chinese market, whilst significant commercially, must be done on the basis that we are confident that our IP is protected. We have exciting opportunities elsewhere, and the change of emphasis in China is not precluding commercial deals being done; the supply of graphene in masks manufactured in China being the first example utilising our graphene technology.

“Monetisation of our technologies is now the focus of the Company’s attention, although we will continue our stated strategy of acquiring additional IP should suitable opportunities arise. With a strengthened balance sheet following the Lanstead placing and the Innovate UK loan, coupled with a particular focus on those collaborative projects that are expected to deliver commercially in the near term we are very well positioned to execute this strategy.

“I would like to take this opportunity to thank our continually supportive investor base and our employees for their hard work as we look forward to the future with continued optimism and confidence.”

Chairman’s Statement

I am delighted to provide my first statement as Non-executive Chairman of Versarien. In the short time since my appointment in June 2020 much has happened at the Company.

We have completed the rigorous process required to achieve the award of a £5 million Innovate UK loan, have redirected our strategy with regard to China and have strengthened our senior management with the appointment of Matt Walker.

Our focus is now very much on the monetisation of the graphene technologies in our portfolio, although we will continue to fill any product gaps as opportunities arise to do so. An update on the collaborations that we continue to work on is provided in the Chief Executive Officer’s Report.

Having exercised the backstop arrangement for our joint venture in China, our intention is to use Beijing Versarien Technology Limited (“BVT”) as the vehicle for channelling sales enquiries back to the UK for the supply of graphene and/or application products into China. Additionally, we are also looking at how products that utilise our graphene can be imported. It is particularly pleasing to see this in the graphene enhanced mask launch recently announced.

The Board of BVT has been appointed and consists of Neill Ricketts, Matt Walker and Bruno Jin, who will also act as General Manager. Bruno, who has worked with Versarien since 2018, has a Bachelor of Engineering degree from Nanjing University and studied at Cambridge University having been awarded a scholarship by the Cambridge Overseas Trust.

The appointment of Matt Walker, following his two year secondment from the UK Department for International Trade, brings with it strategic direction for the Company’s global expansion plans, which it should be noted are focussed far wider than China and the US. Matt, together with our representative, Rachel Kim, have been working tirelessly on a number of opportunities in South Korea. Matt is also currently looking at opportunities in India, Japan and Singapore.

I am particularly pleased with the support that the UK Government has provided to the Company, most significantly via Innovate UK with the provision of a £5 million loan, their first of such magnitude. It is specifically for a project named G SCALE, (an acronym for Graphene-Seat, Concrete, Arch, Leisure, Elastomer), covering a number of Versarien’s existing collaborations, which is designed to enable Versarien to significantly increase its manufacture of quality assured graphene.

Prior to my appointment, the Company completed a £6 million fund raise and sharing agreement with Lanstead, a US headquartered institutional investor who is now our largest shareholder. Having spoken directly with Lanstead’s principal, I am pleased to report that he is very supportive of the Company and its strategic direction. The Versarien team is looking at how it can best advance in the US where early adoption is proving challenging for all market participants.

I would like to thank all the staff and the executive directors for their hard work during the year. The coming year will be important for Versarien as it seeks to monetise its graphene technologies and that will be the focus of the Board’s attention.

James Stewart CBE

Non-executive Chairman

Chief Executive Officer’s Review and Strategic Report

As stated above, this year has been particularly challenging with the Covid-19 pandemic taking full force and effect towards the end of our financial year. As has been reported previously, we are now concentrating on the major collaboration opportunities and these are allied to the £5 million Innovate UK loan (“the Loan”) awarded to us at the end of June 2020. The Loan particularly acknowledges the work we are undertaking, the advancements made and the strategic importance of our 2D materials technology to the UK. The Loan will help Versarien step up its graphene production capacity so that we can expedite the commercial adoption of products utilising graphene enhanced materials.

As we stated would be the case in our announcement on 25 February 2020 the Company intends to use its interim and full year results announcements to provide updates on the status of the Company’s various collaborations and will not make announcements between these unless a disclosure obligation arises. I am therefore pleased to provide an update on our current commercial collaborations as well as a summary of specific funding.

In order to ensure the appropriate focus of the Company’s resources and to ensure that the monetisation of our technologies is now the primary focus of the Company’s attention we have segmented our various collaborative projects. Our primary focus is on those projects that are related to the GSCALE project, whilst still continuing to progress others that are likely to provide medium term returns.

Funded projects

| Funder | Project | Amount | Duration |

| Innovate UK | GSCALE | £5,000,000 | 24 months |

| Graphene Flagship | Aircraft surface de-icing | €350,000 | 36 months |

| Advanced Propulsion Centre | Low carbon technologies | £104,000 | 18 months |

GSCALE collaborations:

| Start date | Description | Current status |

| May-20 | Coats Group Plc | The agreement will see the parties work on four specific projects, which will focus on two different manufacturing processes that use Versarien graphene nano-platelets and graphene inks in different consumer textile applications in the Apparel and Footwear sectors. The agreement follows new research and testing on yarn extrusion featuring the Company’s graphene materials at the Warwick Manufacturing Group and subsequent discussions with an existing collaborative partner of the Company. |

| Mar-19 | Initial order from US company for 12kg of HP-GNP incorporated into polymer masterbatch for down-hole drilling components | Testing on scale up is underway at the customer test facility in Europe and the next milestone is a live drilling test but is subject to ongoing restrictions re Covid-19. |

| Mar-19 | Further collaboration with Chinese Aerospace Company | The parties continue to progress through the work plan created with samples sent for further testing. |

| Dec-18 | MOU China Railway | The project, which involves GEIC and other civil engineering parties, continues to progress well. The testing features trials with various grades of construction materials for different construction applications and are undergoing further analysis. |

| Dec-18 | Collaboration with Chinese Aerospace Company | This longer-term project, which is focused on several materials for different parts continues at an R&D level. Progress dependent upon test results. |

| Aug-18 | Construction materials collaboration with AECOM | Following the launch of the AECOM CNCT Arch at Network Rail facility in Bristol, the product has been subject to further tests, with positive test data reported to date. Discussions underway regarding project delivery/commercialisation. |

| Aug-18 | Sporting goods collaboration | New Polygrene blend being formulated for trial at customer factory. In addition, the companies are collaborating on other shoe development and garments. Programme to resume following lifting of Covid-19 restrictions. |

| Jan-18 | Agreement with global apparel manufacturer, MAS Innovation (Private) Limited | The parties continue to work together on projects with brand partners for sportswear and non-sports wear as well as pre-production trials on base layer garments for own branding. Further projects underway on PPE garments with different material blends that could provide further unique benefits. |

Priority projects:

| Start date | Description | Current status |

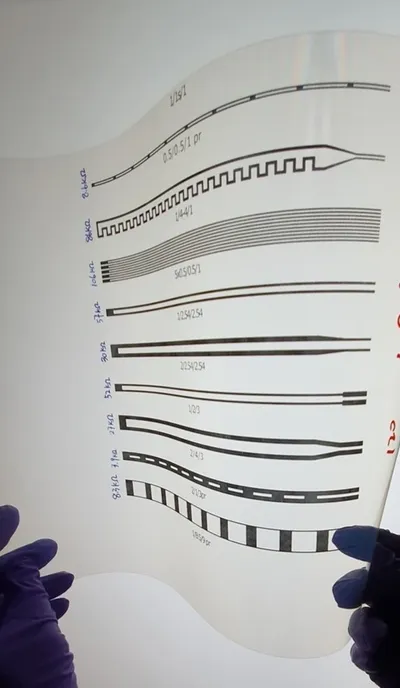

| Apr-20 | Rolls Royce/ GEIC | The aim of the collaboration is to reduce the weight of electrical components, improve electrical performance of 2D materials and increase resistance to corrosion of components in future engine systems.It also involves the development of new reel to reel CVD capabilities applicable to other sectors |

| Mar-18 | Collaboration with world-leading aerospace group | This longer-term project features work on specific parts and continues with WMG and other parties. |

| Feb-18 | Medical technology collaboration at Addenbrooke’s hospital | Following the return to work of the global partner, the parties are now discussing further supplementary funded projects. |

| Feb-18 | Agreement with shoemaker, Vivobarefoot | Further project work, including textiles and leathers has now commenced, following delays due to Covid-19. |

| Dec-17 | Agreement with global chemical major | Project ongoing and awaiting further test results. |

| Nov-17 | Collaboration with global consumer goods company | Following commercial discussions to evaluate cost-benefit value. The customer has agreed to funded testing at its R&D centre based in the UK. The funding forms part of a new joint development agreement agreed between the parties. |

Ongoing Projects (non-priority):

| Start date | Description | Current status |

| Feb-20 | Oxford Advanced Surfaces | Collaboration to work on graphene enhanced surfaces for adhesion and increase in electrical conductivity using Versarien 2D materials. |

| Oct-19 | Refractory Materials Collaboration | Materials have been supplied and tests carried out, the results of which have been assessed and further tests are being carried out. |

| Jun-18 | Commercial agreement with MediaDevil | New product development has focused on the requirements of private label partners and further trials of different eco-friendly material are on-going. In addition, Media Devil are working with the company on other audio project will a well know household brand. |

| May-18 | Consumer goods collaboration for polymer structures in plastics | The project was put on hold by the customer due to production demands during Covid-19 with resumption anticipated later in the year. |

| Mar-18 | Collaboration with Team Ineos for cycling equipment | We are working on material prototypes with other partners which we expect to trial later in 2020. |

Gnanomat

Gnanomat has continued to make progress with its objective of incorporating graphene into energy storage devices.

Recently, some of these nanomaterials have demonstrated not only their suitability to be integrated into the electrodes of such devices, but also have demonstrated a significant improvement over current market standards in tests in industrial prototypes. Gnanomat believes it has now developed its nanomaterials to a level that provides approximately three times the energy capacity of current market reference products and is continuing with further developments.

These findings have opened the door to prospective customers that are now partnering with Gnanomat. At present it is working with companies in the US, Japan and South Korea, among others, to commercialise its products.

In addition, some of the Gnanomat materials have shown significant benefits in other energy storage applications, such as supercapacitors and metal/air batteries.

As a result of the advances achieved and its extensive knowledge base and manufacturing potential, Gnanomat is able to participate in a number of different European funding programmes. These include the Spanish Ministry of Science and Innovation which has granted a €116,000 project to the Company as well as others where application is progressing.

Versarien Graphene Inc

With the Covid-19 pandemic significantly impacting the US, contacting and conducting business with customers in the US has been challenging in recent times. Therefore, the current strategy is to concentrate on larger corporations, which have a further forward vision.

A number of NDA’s have been signed and technical conference calls between prospective customers and the UK development staff held. In addition, trials are ongoing on a project to add graphene for coatings applications. A tyre manufacturer has also expressed its recent wish to move forward with testing despite being at the epicentre of the pandemic.

Gaining traction in the US market is proving challenging, which appears to be in common with many other US graphene companies and these challenges are expected to continue until the worst of the pandemic has abated in the region.

AAC Cyroma

The past 12 months has seen AAC Cyroma focussing on internal efficiency improvements and new business sales in very challenging market conditions. Improved planning techniques, factory process layout changes and scrap reduction activities has resulted in a reduction in direct labour and raw material costs.

A targeted sales strategy has seen new customers placing regular schedules orders, for both injection moulded and vacuum formed work, replacing some lower margin accounts. These include the manufacture and supply of hospital bed and cot mattress panels, injection moulded soil sample core boxes, paint masks, electric vehicle component parts, packaging trays and protective visors for smart PPE.

Graphene enhanced injection moulded products, ranging from packaging trays, construction products and consumer goods, have been successfully moulded using AAC Cyroma’s injection moulding technology utilising a variety of different polymer grades. These products are being tested in conjunction with our partners for live applications and AAC Cyroma continues to work with new partners looking at opportunities whereby graphene-enhanced products can offer product differentiation and structural improvements.

Hard Wear and Metallic Products

Over the past few years Total Carbide has sought to move away from its dependency on the oil and gas sector which it had done reasonably successfully. However, with low oil prices that part of the business which still remains has been badly affected and accelerated the need for the business to diversify.

For example, after two years of tests and development work with an award winning, Norwegian high- tech company, Total Carbide has succeeded in securing orders for the manufacture of parts which reduce the inflow of water or gas in oil wells. It is expected that this will account for approaching up to 10% of future revenues.

Breakthrough technology designed to cut the weight of rockets is being carried out at Westcott and Total Carbide has been working on technology to transform the throat nozzles, which provide the right amount of thrust to propel rockets and satellites.

Currently its throat nozzles are made from heavy tungsten alloys to provide sufficient strength and heat and wear resistance. The addition of Hexotene into a heat resistant ceramic will be used to provide a more lightweight solution. The project is part-funded by the Space Research and Innovation Network for Technology (SPRINT) programme which will help with testing of the new material.

Versarien Technologies’ restructuring at the start of the financial year saw it reduce its less profitable business in order to create space at the Cheltenham site to support the graphene scale up that is now made possible by the award of the Innovate UK loan.

Key performance indicators

As a Group that consists of mature products supporting the development of early stage technology products, we concentrate on the following financial metrics:

| 2020£’000 | 2019£’000 | |

| Group revenue | 8,281 | 9,140 |

| Gross margin percentage | 24% | 27% |

| Loss before interest, tax, depreciation, amortisation, exceptional costs and share based charges | (646) | (1,134) |

| Cash used by Graphene and Plastic Products | (2,685) | (1,305) |

| Cash used/generated by Hard Wear and Metallic Products | 608 | (266) |

| Cash raised/(utilised) by parent (before loans to/from subsidiaries) | (558) | 3,567 |

| Net Cash raised and generated/(used) by the Group | (2,635) | 1,996 |

Current trading and outlook

The current financial year has seen a slow start for the mature businesses with some staff furloughed, some working from home and some working at our factory locations. With the lifting of restrictions, we are beginning to see some indication of our markets recovering, but continue to monitor costs carefully.

The future for the technology businesses looks exciting with the new product launch of the graphene enhanced masks, final testing of Gnanomat products by prospective customers and opportunities for expansion abroad.

The opportunity afforded to us by the Innovate UK loan to scale up our processes will be a main focus for the business going forward as we seek to monetise the opportunities we have.

We remain confident of the future benefits that graphene can bring to society and our shareholders.

Neill Ricketts

Chief Executive Officer