Versarien plc (LON:VRS), the advanced materials engineering group, announced today the completion of the construction phase of a civil engineering project being undertaken by the Company with a subsidiary of Costain Group plc (LON:COST.

Versarien has been working with Costain to develop designs for, and bring into production, a 3D printed concrete headwall for use in highway construction projects, part of the Digital Roads of the Future Partnership, a collaboration led by the University of Cambridge, Costain and National Highways, of which Versarien is a partner.

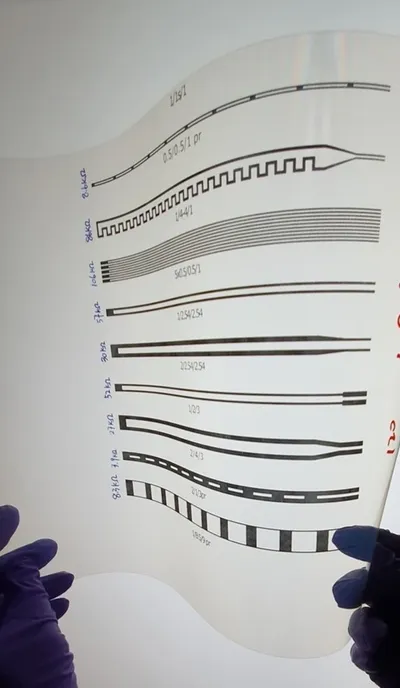

Traditionally, these headwall structures have been made from precast concrete, utilising extensive steel reinforcement, and with limitations on the shape of structure that can be precast. Utilising Versarien’s technical expertise and an AACM (alkali activated cementitious material), printed using the latest 3D printing technologies, the Company has worked with Costain to create a curved form headwall that is naturally strong and therefore does not need the same reinforcement. This approach has enabled steel to be entirely removed from the walls of the structure.

During the 3D printing process, a series of sensors have been installed in the structure according to a scheme provided by a team from Cambridge University, who are working on the National Highways Digital Roads initiative. This sensor data includes temperature and movement from the point of printing all the way to the structure’s performance on site. The constructed headwall is due for delivery and installation on one of Costain’s projects for National Highways shortly.

Neill Ricketts, Chief Executive Officer of Versarien, said: “We are delighted to have partnered with Costain to produce this innovative structure that we believe provides significant benefits over those produced using traditional manufacturing techniques. In utilising Versarien’s materials engineering expertise and understanding of the latest techniques, we have highlighted how new technologies can be employed to provide a solution to improve product performance, lower cost and reduce the carbon footprint. We believe this represents the first use of 3D construction on a National Highways project and we look forward to the headwall being installed, demonstrating the viability and attractiveness of using this technology and Versarien’s know-how on future projects.”