Versarien Plc (LON:VRS), the advanced engineering materials group, has today announced its unaudited results for the year ended 31 March 2021.

Operational highlights

● Acquisition of chemical vapour deposition graphene assets and IP from Hanwha Aerospace Company Limited, South Korea, for a consideration of 11 million ordinary shares in Versarien valued at £4.34 million

● Awarded £5 million Innovate UK loan with £2.26 million received during the year for the Company’s GSCALE project (an acronym for Graphene, Seat, Concrete, Arch, Leisure, Elastomer)

● Awarded a £1.95 million development agreement by the Defence, Science and Technology Laboratory (“DSTL”), a part of the Ministry of Defence

● Award of EU Grant of €357,000 to Gnanomat for scale-up and development of electrode materials

● Launch of graphene enhanced protective face masks utilising PolygreneTM, Versarien’s graphene enhanced polymer

● Project completed with Rolls Royce and the Graphene Engineering Innovation Centre to understand and create technological advances in the aerospace sector utilising chemical vapour deposition (CVD) graphene and other 2D materials

● Formation of the Versarien Graphene Advisory Panel (“VGAP”)

● Board strengthened by the appointment of James Stewart CBE as the Company’s new independent Non-executive Chairman

● Appointment of Dr. Stephen Hodge to the Company’s Board as Chief Technology Officer

Financial highlights

● Group revenues of £6.6 million (2020: £8.3 million)

● Adjusted LBITDA* of £1.8 million (2020: £1.6 million)

● Reported loss before tax of £8.1 million (2020: £4.7 million) after a non-cash share based payments charge in the year of £1.2 million (2020: £1.2 million) and a non-cash £3.3 million charge arising from a reduction in the IFRS 13 valuation of the Lanstead Sharing Agreement (2020: £1.0 million gain)

● Cash at 31 March 2021 of £2.4 million (31 March 2020: £1.7 million)

● Issue of 8.75 million ordinary shares re-invested into an 18-month sharing agreement with Lanstead Capital Investors LP (“Lanstead”), a US headquartered institutional investor

● Net assets of £16.5 million at 31 March 2021 (31 March 2020: £15.7 million)

*Adjusted LBITDA (Loss before, interest, tax, depreciation and amortisation) excludes exceptional items, other gains/losses and share based payment charges

Post Period highlights

● £1.93 million strategic investment in Versarien by Graphene Lab Limited including 5% royalty agreement and 2% trademark agreement on sales

● Acquisition of Spanish graphene manufacturing assets to provide up to an additional 100 tonne powder capacity per annum

● Orders placed for the purchase of ink scale up equipment to give up to an additional 12,000 litres of ink capacity per annum

● Lease signed on new dedicated graphene production facility in Longhope, Gloucestershire

● Textile supply agreement signed with Crosslete and discussions ongoing with multiple garment suppliers

● Agreement signed with one of the world’s largest packaging companies to evaluate graphene-based coatings

Commenting, Neill Ricketts, Chief Executive Officer of Versarien, said:

“Despite the challenges arising from the pandemic, which not unexpectedly impacted our mature businesses, we have continued to focus on the commercialisation of our graphene technologies and in particular through the GSCALE project. I am pleased to report that the manufacturing scale up is advancing in tandem with the progress on commercialisation of the project’s applications.

Highlights include the development and supply agreements for textiles and the number of infrastructure opportunities following the successful pourings of graphene enhanced concrete. In addition, we are working with multiple industrial partners to develop composite structures for automotive, aerospace, defence and rail. We have also demonstrated 40% improvement in concrete strength, 30% increase in tyre rubber stiffness and have applied to trademark GrapheneWearTM as part of the textile commercialisation. With this we continue to pursue our strategy of global positioning to ensure that our products can be supplied to multiple sectors in multiple markets.”

Chairman’s Statement

Despite the challenges presented by the Covid-19 pandemic, I am pleased to report that the Company has continued apace with its strategy to commercialise its graphene technologies and expand its portfolio of graphene products. In doing so, it is supported by the UK Government through the Innovate UK loan of £5 million and the £1.9 million development contract from DSTL as well as through the continued support of Lanstead.

In December 2020, we expanded our product portfolio with the acquisition of chemical vapour deposition (“CVD”) assets and IP from Hanwha Aerospace Company Limited (“Hanwha”). The CVD plant and equipment has now been successfully transferred from Hanwha to its new premises leased by Versarien Korea Limited (“VKL”), with re-commissioning underway. We have been assisted by our South Korean partner Graphene Lab Limited (“GLL”) which, as previously announced, took a 15% stake in VKL as well as subscribing £1.93 million of new capital to Versarien. The VKL board has also been strengthened by the appointment of three new local directors.

Significant progress has also been made with the GSCALE project, for which we have now purchased additional graphene production equipment at a cost approaching £1 million. Particular application highlights include the impressive results in concrete, where the mechanical properties have been improved and surface cracking reduced by using graphene additive, and in textiles, where development and supply agreements have been signed.

The DSTL contract continues to progress well with revenues of £0.3 million in the year under review and a further £1.6 million anticipated for delivery this financial year.

I would like to thank all our staff for their continued endeavours, particularly during the pandemic, without which we would not have been able to make the progress that we have. I look forward to the Company reporting further progress during the current financial year.

James Stewart CBE

Non-executive Chairman

Chief Executive Officer’s Review and Strategic Report

The acquisition of the Hanwha CVD graphene assets and patents, the setting up of VKL in South Korea and our partnership/investment from GLL continues our strategy of establishing a global platform for our technology. We now have operations in the United Kingdom, Spain and South Korea as well as a sales presence in the USA and in China. This global footprint will facilitate our commercial development as the global graphene market begins to gain traction.

We have continued to progress graphene enhanced mask sales which can only be achieved if the required standards have been met. We now have seventeen certificates and have met the following standards:

● GB2626-2019 (general standards)

● ISO 18184:2014(E) (antiviral)

● GB/T 20944.3-2008 (anti-bacterial)

● GB/T 20944.2-2007 (anti-bacterial)

● EN 149-2001+A1-2009 (filtering, clogging, cleaning and disinfecting)

In addition, our masks have been independently tested and proven not to emit graphene particles which will enable us to register them as nano-safe masks.

The following sections describe the activities of the business in accordance with the segmental analysis adopted since 2017. Since the year end, the Board has approved the leasing of new dedicated graphene manufacturing facilities in Longhope, Gloucestershire, which will house the recently acquired Spanish plant and equipment, the new ink production equipment and the existing graphene production equipment currently located in Cheltenham. The continued focus on graphene means that the non-core aluminium operations of Versarien Technologies Limited are being wound down and in future the segmental analysis will be split between technology businesses and mature businesses.

GRAPHENE AND PLASTIC PRODUCTS

Domestic Graphene

The UK operations are centred around the GSCALE project funded by the £5 million Innovate UK loan and I am pleased to summarise the significant progress during the year and subsequently in each of the work packages:

Work Package G (Graphene)

The objective is to scale production of high-quality graphene to greater than 10 tonnes per annum to meet the expected demand from the projects described below. Our key partners include graphite producers and miners, chemical suppliers and equipment manufacturers incorporating recycling and reuse as an environmentally friendly and economic production process.

Post period end, we have purchased two large scale systems for ink production and ancillary equipment at a cost of £342,000, which will increase ink production capacity from up to 3,000 litres per annum to up to 15,000 litres per annum, depending on formulation.

In addition, we have purchased the graphene manufacturing assets (including control systems, laboratory test equipment and graphene process IP) used by a former competitor in Spain at a cost of €600,000 which will be used to manufacture graphene that can be used, amongst other applications, in energy storage devices and elastomers. This will give a capacity of up to 100 tonnes of graphene per annum when fully commissioned and developed.

These assets will be located in a new dedicated 14,000 square foot facility in Longhope, Gloucestershire, together with the existing graphene production equipment currently in Cheltenham, where the lease ends in September 2021.

Work Package S (Seat)

The Seat package grew from previous developments of lighter, flame-retardant seat backs for the aerospace industry involving the dispersion of graphene in various thermoset systems used in fibre reinforced polymer composites.

We have now extended this to also include rail products, including interior applications and door panels. Automotive opportunities in this field are expanding too with the growth of electric vehicles requiring structural light weighting to enable increased range performance.

Batch size increases have required the design and procurement of resin dispersal scale up equipment, including the purchase of a large processing vessel that will take our current graphene/resin dispersion from five litres per day to up to 100 litres per day.

A rail seat back mould tool has been procured, manufactured and delivered to 2-DTech at The University of Manchester’s Graphene Engineering Innovation Centre (“GEIC”) for trials to develop our product and to be made available to the industry for their trials and testing requirements including mechanical and fire/smoke tests.

Work Package C (Concrete)

The Concrete workstream principally focuses on the reduction of construction CO2 emissions, with government programmes requiring a plan for net zero carbon by 2050. Graphene can help drive efficiency (i.e. enabling faster, cheaper solutions) and increase asset life through reduced micro-cracking, low permeability and less ferrous rebar corrosion.

We are in advanced discussions with large infrastructure contractors for new rail, road and water applications with projects and trials / demonstrators being planned or already being built.

Trials with a traditional CEM1 concrete mix and the addition of Versarien’s graphene show the following (all tests have been undertaken by an independent test house):

● Improved compression strength (+38%)

● Improved flexural strength (>14% – 45%)

● Increased split tensile strength (>15%)

● Improved water permeability (> 200% – 0mm to 2mm)

● Faster curing without micro-cracking

● Increased corrosion resistance

Further trials with an international ‘readymix’ concrete manufacturer have developed a graphene enhanced, low carbon, pumpable, commercial mix as typically available at any UK readymix site. This graphene enhanced concrete produced similar performance results as the CEM1 by utilising a fraction of a percent of graphene in the concrete.

Our chosen development product for the construction industry is based on our GraphinksTM products. This is an easy to use (simply add with the water) product, with excellent mixing results, offering workability and performance using the construction industry’s regular admixture control systems.

With regards to additive manufactured concrete printing, we are progressing the purchase of a £250,000 robot printing system that will produce graphene enhanced 3D printed structures with a reach of 3 metres in every direction and up to 5 metres high. A significant rail infrastructure project is already engaged in discussions with a view to Versarien’s technology resolving current challenges in their programme. The robot printing allows complex structures to be printed in situ and in open or confined spaces near live railway lines without the need to close the line. The potential benefits to the project include improved operator safety (as the robot can print remotely from its operator), less ‘live line’ downtime (trains can keep running) and efficient and economic delivery of enhanced concrete structures in the rail environment. Similar opportunities are recognised across the road and water sectors too with projects being planned.

Work Package A (Arch)

The Arch workstream covers all of our thermoplastic development and commercial exploitation through enhanced graphene characteristics across:

● Consumer and commodity thermoplastics;

● Engineering polymers; and

● Speciality plastics

Development under these three themes include:

● Polyolefin compounds and masterbatches being developed for extrusion moulded products (joint development agreement with a global consumer product company).

● Graphene enhanced thermoplastic polyurethane (TPU), nylon PA12, cellulose acetate, and polycarbonate trials performed and prototypes developed for use in future ranges of eyewear frames and lenses for an eyewear manufacturer – strengths can be improved by 30% enabling longer life products.

● Particular focus on the use of graphene to enhance recycled polymer products in such a way that the mechanical performance of the 100% recycled product is equal to a virgin polymer, thus breaking the need for addition of climate challenging oil based raw materials.

● Biopolymers – AAC Cyroma will supply an initial batch of portable suction devices for clearing blocked airways in emergency and chronic health conditions which has the potential to make current technology obsolete. This will be manufactured from bio-derived nylon polymer.

Work Package L (Leisure)

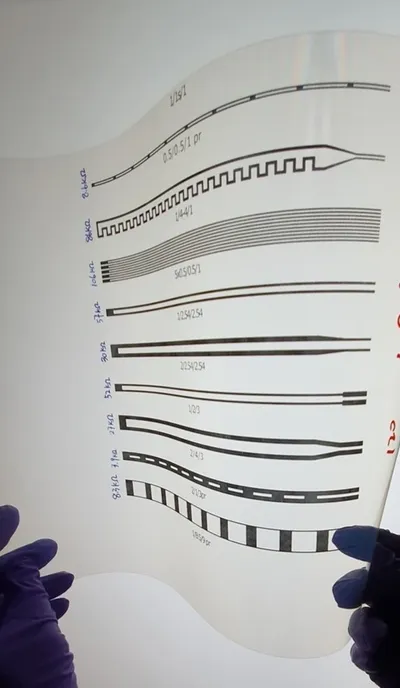

The Leisure workstream surrounds the use of graphene inks and graphene nanoplatelets, primarily within the textile sector. Our R&D work gives attention to three distinct processes; print, coat and blend, where we have key industry partners including MAS Holdings and Coats Plc.

The print process, which utilises GraphinksTM, has now been scaled to pilot level production and this has allowed us to develop commercial discussions with both new parties and collaboration partners. Along with our key industry partners, we have been able to offer those customers a new range of active wear garments in men’s and women’s designs, which will see the benefits of thermal regulation, wicking, drying and water repellence given to wearers.

Currently we have sample garments with a number of well-known active wear brands around the world and have signed a supply agreement with Canadian boutique active wear brand Crosslete, who will introduce a new line of men’s and women’s garments featuring the print technology. We expect to make further announcements in this area in due course taking into consideration new product seasonal launches, commercial confidentiality and covid recovery plans of global supply chains.

The benefits of the print technology were underpinned by extensive industry testing carried out by BGGT Ltd./Shirley Technologies Ltd., a leader in its field, whereby tests were carried out in accordance with industry standard test protocols including BSENISO/BSEN/BS/AATCC methods.

In addition to this, the Company is currently collaborating with the University of Gloucestershire, which involves a number of athletes and focuses on elite performance and how the print technology can be optimised for elite level participation.

Work Package E (Elastomers)

Elastomers aims to develop large-scale graphene enhanced elastomer masterbatches for two key sectors, oil and gas and automotive tyres, but is applicable to other sectors, in particular shoes. Lab scale tests are showing good results and we are creating a solid foundation of knowledge on which to build our future business ventures in Elastomers.

The impact of the Covid-19 pandemic has seen R&D in this sector scaled back, however, our project continues if somewhat delayed. We have seen really good improvements over control rubber samples at the bench scale and having agreed a pricing structure we are expecting to move to large-scale trials in Q3 2021.

The objective for rubber formulation in tyres is to reduce rolling resistance while not sacrificing grip or wear resistance. We believe that graphene has an important part to play in achieving this. Ongoing tests have made great strides toward this, but increasing wear resistance is more complex. However, in the last set of tests conducted we saw a slightly more than three-fold reduction in wear compared to the best of the other samples tested.

We have undertaken benchmark testing of shoe competitor products in order to place our results into context. Of note is a 33% reduction in wear in a graphene outer sole formulation under development compared to a leading brand of graphene footwear. We are also seeing good improvements in mechanical properties across the board. Following increased demand masterbatches have been distributed globally in order to facilitate manufacturer testing and small-scale production trials.

With every test that is undertaken we gain further valuable information on how our products interact with elastomeric compounds. Good solid progress has been made, interest in graphene enhanced elastomers is increasing and we are moving closer to bringing products to market which we will do so on a foundation of solid scientific understanding.

Overseas Graphene

Versarien’s stated strategy is to expand globally and I am pleased to report on our further progress.

Versarien Korea Limited (“VKL”)

The year under review saw success with regards to acquisition and expansion into South Korea. The chemical vapour deposition equipment and IP acquisition from Hanwha (originally Samsung’s technology) means that the Group now has added another important graphene manufacturing capability within the overall portfolio; whilst the setting up of a new graphene production and R&D facility in South Korea in conjunction with a CVD expert partner allows Versarien to exploit one of the largest markets for electronics and technology in the world.

The move to the new R&D facility was completed in June 2021 and we are now in the process of utility set-up and commissioning in order to produce our first CVD graphene samples and optimise the product quality.

The main focus of business in the short term will be to provide a turnkey CVD graphene production solution, securing or participating in government and other institutional projects, and developing various optical and electronic applications.

Versarien Graphene Inc. (“VGI”)

VGI is making good progress in the US market although it has been slowed by the pandemic. Long term relationships have been established with a number of large players including one of the world’s largest paints and coatings companies which has completed the first stage 1000-hour anti-corrosion salt spray trials with promising results using graphene as a substitute for zinc. That company is now working on multiple projects with Versarien and we are optimistic that the graphene will perform similarly in enhancing them.

Gnanomat (“GNA”)

In the year under review GNA expanded the scope of its nanomaterial applications whilst still concentrating on energy storage, where excellent performance was seen when their materials were integrated in electrodes of asymmetric pseudo capacitors.

The catalytic properties of GNA’s materials were also optimised and tested in other applications, such as secondary metal-air batteries, with very good results in charge, discharge and stability. Findings in this application are currently in the process of intellectual property protection. Work is also ongoing in other energy storage applications such as fuel cells.

The versatility of the technology and the synergies within Versarien allows GNA products to be used in other new potential applications such as providing antiviral effects against SARS-CoV-2 and electromagnetic interference shielding.

GNA was awarded a grant of €357,000 from EU funding for the INN-PRESSME project in collaboration with other industrial partners. This grant will be used to upgrade Gnanomat’s pilot plant and to develop new products in collaboration with its partners, as well as to accelerate the development of products to commercialisation. At present, Gnanomat has collaborations in seven different industrial applications.

Beijing Versarien Technology (“BVT”)

BVT, our wholly owned subsidiary in China, is continuing to work with a Chinese supplier on the graphene enhanced face mask project. Some variants including a graphene enhanced children’s mask and an FFP3 mask have also been developed.

Going forward, it is intended BVT will source more opportunities from China under the GSCALE framework agreed between Innovate UK and Versarien, whilst ensuring that Versarien’s China operations are carried out fully in line with the letter and spirit of the UK’s National Security and Investment Act 2021.

Future expansion plans include establishing a presence in other potentially lucrative global markets, by way of exporting, acquisitions and/or partnerships, as and when the right opportunities arise. We will also work towards growing our current international operations, which will in turn increase our own capability and reach.

Plastic Products

AAC Cyroma Limited (“AAC”) has, over the last 12 months, remained operational throughout the Covid-19 pandemic and lockdown period supporting the NHS with the supply of hospital bed panels and visors, along with products for utility service providers.

Turnover is showing some recovery towards pre-pandemic levels with several new projects and opportunities. The focus for the current financial year for AAC is the conversion of these opportunities into new business and to further progress opportunities for supplying graphene enhanced plastic products in conjunction with the Company’s new Longhope operations.

HARD WEAR AND METALLIC PRODUCTS

The focus on the opportunities afforded by graphene together with the market challenges of Covid-19 have resulted in the decision to exit the non-core aluminium business of Versarien Technologies Limited based in Cheltenham. The lease comes to an end in September 2021 and a run-off to customers is currently in progress. The company has been re-named Versarien Graphene Limited and will be used as the revenue generating entity for UK graphene sales whilst 2-DTech Limited and Cambridge Graphene Limited will continue as the UK research and development arms of the graphene business.

Total Carbide Limited is a manufacturer of tungsten carbide wear parts and sells to a global customer base covering 40 different industries producing bespoke products for a wide spread of wear applications. These range from all aspects of the oil and gas industry, through measurement tools and cutting knives to difficult complex breakthrough technology for aerospace and defence applications as well as providing nozzles for space propulsion.

Despite being a challenging year, the company won national and regional awards for its work with apprentices and young people.

Current trading and outlook

There are indications that trading is beginning to return to pre-pandemic levels in our mature businesses, but the economic environment remains uncertain and the Company remains vigilant around costs. Much more importantly, however, the graphene prospects in both the UK and abroad are extremely exciting with our transitioning from laboratory to real world demonstrators in multiple sectors including defence, automotive, aerospace and construction; in particular, interest in using our graphene in large infrastructure projects and in textiles.

We have been fortunate to extend our team with key hires in South Korea and the UK, including project managers for our key projects as we make this transition into the commercial world. I look forward to providing further updates on customer projects in due course. We now have a strong platform of licensable IP, large global commercial partners, significant support from the UK government, especially around security, and a clear path to revenue from innovative products.

Key performance indicators

As a Group we concentrate on the following financial metrics:

| 2021 £’000 | 2020 £’000 | |

| Group revenue | 6,567 | 8,281 |

| Gross margin percentage | 22% | 24% |

| Loss before interest, tax, depreciation, amortisation, exceptional costs, share based charges and other gains/losses | (1,761) | (1,633) |

| Cash used by Graphene and Plastic Products | (2,544) | (2,685) |

| Cash generated by Hard Wear and Metallic Products | 94 | 608 |

| Cash raised/(utilised) by parent (before loans to/from subsidiaries) | 3,152 | (558) |

| Increase/(decrease) in cash and cash equivalents | 702 | (2,635) |

Neill Ricketts

Chief Executive Officer