Versarien Plc (LON:VRS), the advanced engineering materials group, has announced its unaudited interim results for the twelve months ended 31 March 2022. As announced on 24 February 2022, the Company’s accounting reference date has changed from 31 March to 30 September.

Financial Highlights

| • | Group revenues from continuing operations up 34% to £7.63 million (2021: £5.69 million)* |

| • | Graphene revenues up 170% to £1.89 million (2021: £0.70 million) |

| • | Adjusted LBITDA** for continuing operations reduced by 45% to £1.04 million (2021: £1.88 million) |

| • | Reported loss before tax from continuing operations of £5.14 million (2021: £8.08 million) |

| • | Reported loss for the period of £5.20 million (2021: £8.07 million) |

| • | Cash of £3.10 million at 31 March 2022 (31 March 2021: £2.36 million) |

*Excludes discontinued revenues of £0.53 million (2021: £0.88 million)

**Adjusted LBITDA (Loss Before Interest, Tax, Depreciation and Amortisation) excludes Exceptional items, Share-based payment charges and Other losses)

Operational/Manufacturing Highlights

| • | Relocation to new dedicated graphene production facility in Longhope, Gloucestershire to significantly expand capacity |

| • | 10,000 square foot floor slab laid for new Versarien innovation centre using the Company’s CementeneTM and PolygreneTM enhanced concrete |

| • | Acquisition of Spanish graphene manufacturing assets transferred to Longhope during the year and in process of commissioning to provide up to an additional 100 tonne powder capacity per annum |

| • | Equipment to scale up graphene ink production capacity by an additional 12,000 litres per annum delivered and commissioned |

Partnerships/Commercialisation Highlights

| • | Commercial agreement signed with Superdry to produce graphene enhanced garments and discussions ongoing with multiple other garment suppliers |

| • | Grant agreement signed and project completed to support the development of Pseudo-Capacitor technology aimed at zero emissions for port-side infrastructure |

| • | Successful on-time delivery of Defence Science and Technology Laboratory (“DSTL”) contract within specification |

| • | Royalty agreement signed with Gerdau S.A. for the distribution of graphene masks primarily in Latin America |

| • | Collaboration signed with US-based Flux Footwear LLC, an adaptive footwear company, to supply graphene enhanced elastomers |

| • | Launch of 3D printed concrete “Lunar” lifestyle pods using Cementene™, Versarien’s graphene-enhanced cement |

Funding Highlights

| • | £1.93 million strategic investment in Versarien by GrapheneLab Co. Ltd., South Korea, together with royalty and trademark agreements |

Post Period Highlights

| • | Sports brand Umbro has announced it will integrate Versarien’s Graphene-Wear™ technology into its “Elite Pro-Training Kit” range for the spring/summer collection 2023 |

| • | GoToGym in South America are launching active-wear incorporating Versarien’s Graphene-WearTM technology |

Neill Ricketts, CEO, commented:

“The period has seen the financial benefits of the DSTL contract focussed on understanding the benefits that graphene-loaded materials may bring to defence applications with Group revenues from continuing operations up 34% and reported losses significantly reduced. Alongside the expansion of our production facilities in Longhope we continue to progress the applications in which graphene can be used with a view to launching new graphene enhanced products over the coming months. This is a natural follow on from the successful finalisation of the DSTL contract and the near completion of the GSCALE development projects.

“In parallel, customer testing continues to prove successful and we are seeing increased interest from global companies in signing development agreements that may, in time, lead to significant future revenues whilst at the same time we are looking to expand our global footprint and enter into agreements with the right strategic partners for the business, in part helped by having passed the accreditation of the Graphene Council.”

Chair’s Statement

I am pleased to provide this, my first statement as Non-executive Chair of Versarien, relating to the first twelve months of the extended 18-month accounting period. In the interim report for the first six months we stated that we would be concentrating our graphene activities on the construction and textile sectors, utilising our ability to help improve the environment by using graphene to reduce CO2 emissions, reduce weight and improve recycling.

We continue to expand our production capability at Longhope, Gloucestershire, and develop our international footprint and product portfolio with the objective of being a global player in the graphene market. At the same time monetisation of the technology remains a priority and the progress made since my appointment a few months ago is pleasing to see.

We are engaging with a number of international textile brands to launch garments in the coming seasons and have launched our Graphene-WearTM website to showcase what can be achieved.

CementeneTM, our graphene admixture, has been used in a number of concrete pours, providing validation for the technology. The next stage will be to obtain the necessary accreditations to allow full-scale commercialisation, a process which is underway.

Whilst we focus on our objective of monetisation it is also vital that we maintain a pipeline of development opportunities that will provide future revenues. Global packaging companies are now showing increased interest in how graphene can aid sustainability and development agreements are in place. Participating in the UK’s Digital Roads for the Future programme also affords greater opportunities in UK infrastructure projects.

In concluding, whilst we are pleased with the progress made we cannot ignore the fact that the pandemic and recent macro-economic events have provided a challenging environment, especially as we have a global footprint to our operations. Whilst these factors have delayed certain near-term projects, it has not affected our objectives and we remain acutely aware of our shareholder’s expectations.

I would like to thank all our staff for their continued endeavours and very much look forward to reporting further progress.

Diane Savory OBE

Non-executive Chair

Chief Executive Officer’s Review

I am pleased to report on the progress that the Group has made, particularly in pursuit of solutions to the environmental challenges we all face. Reducing CO2 emissions, light-weighting, electrification and recycling are all matters where Versarien’s advanced material technology can play a significant role.

The DSTL contract has been successfully delivered and we are having ongoing dialogue with the UK defence sector. The development work under the GSCALE project is nearing completion, and under the terms of the Innovate UK loan the next two years will be focussed on commercialising the developed technology. Monetisation of this and Versarien’s portfolio of other opportunities remains the focus both in the UK and globally. The highlights of our recent progress are set out below.

Construction:

The global construction industry is one of the biggest contributors to CO2 production, accounting for c.39% of energy and process-related carbon dioxide emissions with concrete alone contributing c.8% of the world’s CO2 emissions. A small amount of graphene added to concrete can offer a way of significantly reducing CO2 emissions, as well as increasing the strength and durability of the concrete, whilst reducing costs through less labour and steel. With the UK and EU objectives of drastically reducing carbon emissions by 2030 and for Europe to be a carbon neutral continent by 2050, the development of CementeneTM and PolygreneTM products provides a valuable societal and economic benefit.

The global ready-mix concrete market is forecast to reach US$1,375bn by 2028 and it is estimated that the global market for graphene included in cement could be approximately £900 million per annum by 2030. Obtaining a significant share of that market is a primary focus for us. At our facilities at Longhope we conducted a 10,000 square foot pouring of our graphene-enhanced concrete for the Company’s new innovation centre. The graphene-enhanced polypropylene fibres eliminated the need for steel rebar, thereby reducing costs and CO2 emissions.

We have also demonstrated the efficiency of using 3D printed graphene enhanced cement with the production of the Lunar Pod, a 3D printed graphene enhanced concrete dwelling which has uses from garden offices to humanitarian shelters. The Lunar Pod was designed to showcase our technology and since its launch has proved to be a valuable marketing tool.

Having demonstrated the technical viability of our graphene enhanced cement, the next stage is to gain the required accreditations under BS EN 8500. Further internal testing is underway to meet BS EN 934-2.

Textiles/footwear and leisure-wear:

Further to previous announcements regarding the collaboration with a prominent global sports and fashion wear manufacturer, the customer, Umbro, has confirmed, post period end, that they will launch a range of graphene-enhanced garments as part of their Elite Pro-Training Kit range which will be available for sale in the spring/summer collection in 2023. The garments will be available in several countries around the world and will feature the Versarien Graphene-WearTM technology and trademark.

Following a period of collaboration, our strategic partner in South America, GoToGym (a venture capital backed business), is launching a new range of active wear garments featuring Versarien’s Graphene-WearTM technology and trademark. GoToGym is working with retail partners in North and South America with the garments to be manufactured in Brazil.

Following delays caused by the Covid pandemic in Sri Lanka, we are working with our partner MAS Holdings on a number of projects, which involve the commercial team, MAS Active, and the development team at Twinery, Innovations by MAS. The projects are a result of further development work carried out at The Royal College of Arts (Textile Division) which was able to further develop the printed graphene ink technology in both ink designs and different fabric compositions.

We are pushing forward with applying our Graphene-WearTM ink technology to Superdry’s core fabrics that will be used to create garments for a 2023 launch. Print trials are underway with their supply chain partners and once completed, it will scale up into production. We will be looking to establish a trademark licence royalty agreement for the products sold which we expect to be a framework for future projects with the company.

We are working closely with a niche fabric and garment manufacturer with capabilities here in the UK and the Middle East. We will be applying our Graphene-WearTM ink technology to a range of their fabrics for them to manufacture sportswear garments. They will be selling these garments to their UK customers and also into the Middle East where the company has established teamwear and retail supply channels.

We have developed several Graphene-WearTM rubber compounds with our customers, one of which has been used to create the outsole component of the Flux AdaptMid athletic shoe. Flux has completed the prototyping stage and the shoes are ready for mass production. Versarien is offering the first 500 pairs off the production line in the autumn-winter 2022 season for the UK market (available for pre-order now). Flux will be placing the shoe on sale in the USA market immediately following this. We will be receiving a trademark licence royalty on each pair sold.

We have supplied an initial 20kg of our Graphene-WearTM rubber compound to a major UK apparel manufacturer for them to mould into prototype outsoles and outsole inserts, that they will be testing for performance parameters.

We have launched our Graphene-WearTM website https://graphene-wear.com to showcase the technologies that we offer. Alongside this, the Company’s recently published white paper shows the scientific validation behind our technology and offers data points for our customers to view and assess.

We have been working with Inspecs Group to develop graphene enhanced eyewear products that improve frame strength and durability with initial technical tests proving successful. Rollout is anticipated in 2023 and further information will be announced in due course.

The graphene market for the textiles and footwear sector is estimated to be approximately £400 million per annum by 2030 and consequently this sector remains a high priority for Versarien.

Automotive

There are significant weight, structural and cost-saving benefits to using graphene-enhanced carbon fibre reinforced polymers (CFRP) in the automotive sector particularly with regard to vehicle weight reduction which improves range for electric vehicles and fuel consumption for internal combustion engined vehicles.

As stated in the first interim report for the period, the Lotus Evija bonnet was successfully developed as part of the Technology Developer Accelerator Programme and further development will continue as the parties look at optimisation of the process for use in any body panel. This, together with the results of the DSTL project are enabling further light-weighting development, including a new bio-based resin with a reduced carbon footprint.

Graphene also has the potential to enhance the performance of tyres. It can reduce the rolling resistance that, in turn, increases the fuel efficiency of the vehicle or, in the case of an EV, offer increased range.

We are now coming to the end of the initial lab scale tests for Enso Tyres, with. the next step to repeat the most promising lab scale tests with a second independent test house to ensure we have robust test data to base any future prototype tyres upon.

The graphene market in the automotive sector is forecast to be £300 million per annum by 2030, so continues to be a focus for Versarien.

Aerospace

Graphene applications in the aerospace industry remain in the early stages of research with light-weighting, fire retardancy, ice protection systems, lightning strike protection and electrification among the applications currently being explored.

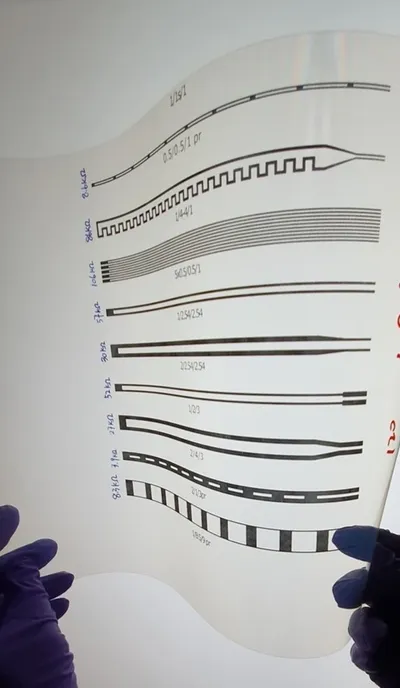

We are at month 24 of 42 in the SpearHead 10 GICE project led by Airbus, with a return to face-to-face meetings following Covid restrictions. Versarien has been developing graphene heater mats to be integrated into several aircraft demonstrators and has had the technology validated to Technology Readiness Level 3 (“TRL”) (Airbus internal TRL scale 1-6). These heater mats are due to be integrated into the various aero foil structures and have been through preliminary icing wind tunnel testing prior to a comprehensive icing wind tunnel campaign later this year.

Within the Graphene Flagship, Versarien is also working with SpearHead 11 project SafeGraph, with the graphene heater mats a case study for understanding the Lifecycle Analysis (LCA) and exposure to nanomaterials during the various stages – e.g. graphene production, heater mat manufacture and integration, during operation and at end-of-life.

Steve Hodge, the Company’s CTO, also maintains an active role as part of the Graphene Flagship’s ECHA-REACH working group.

The graphene aerospace market is estimated to be approximately £70 million per annum by 2030 so continues to be a focus for the Company.

DSTL Contract

The Company contracted with the UK’s Defence Science and Technology Laboratory (DSTL) in 2020 to undertake a package of work to better understand the benefits that graphene-loaded materials may bring to defence applications. This project completed successfully on schedule by 31 March 2022 with the delivery of demonstrators in two areas of application with some final reports to be delivered post-period end. The manufacture of the demonstrators has been proven to be a realistic practical undertaking utilising the materials developed on the project.

One of the project work streams involved military bridging, where a quarter scale bridge designed by Versarien was modelled using finite element analysis (FEA) and manufactured from graphene-enhanced carbon fibre polymer composite with minimal metallic elements. The bridge underwent rigorous mechanical testing to validate FEA models and will be housed at our Longhope facility.

Exploitation plans have been developed and there is now ongoing discussion with DSTL and industry OEMs to explore and capture exploitation opportunities in the short, medium and long terms. The project was a first for the Company and while it has delivered on its technical requirements, the fruitful and constructive relationship that has now been developed with DSTL has put the Company on a firm footing for future engagements with the UK defence sector.

United States of America

We continue to make good progress in the US market, adding new customers, signing new NDAs, entering into new projects, and selling samples. Our long-term relationships are moving towards monetisation with Rust-Oleum, (a coatings company), having now completed long term corrosion testing. We have performed companion electrical corrosion testing in our UK labs, and the results are good. The material is expected to be used in “professional grade” corrosion inhibiting primer as soon as Versarien Graphene Inc. attains the appropriate certification.

We have received our first order for sample material from NASA where our graphene will be investigated for space-craft coating applications. We are also working with a major fabric and yarn manufacturer to include Versarien’s graphene in ballistic protection, stab resistant, flame retardant and abrasion resistant garments as well as a high-end bicycle chain lubrication manufacturer where Versarien’s graphene materials have performed exceptionally well in preliminary tests.

Interest is being shown by various US universities in understanding more about CementeneTM with a view to including us in their customer led concrete projects where significant US Government funding for infrastructure is in place.

South Korea

Good progress has been made at Versarien Korea Limited (“VKL”) where strong partnerships have been forged with academic and industrial partners. The core focus has been on chemical vapour deposition (“CVD”) growth optimisation with a portfolio of CVD graphene products on different substrates to be launched pending independent testing through the Graphene Flagship’s characterisation services. VKL is also looking at opportunities to sell Versarien Graphene Limited’s CementeneTM and Graphene-WearTM products in Korea.

South America

Graphene enhanced masks for COVID protection continue to be of interest to the Brazilian market where the licence agreement with Gerdau providing a royalty. Gerdau is currently going through the process of getting the masks cleared by the Brazilian Health Authorities after their initial order of 270,000 units.

Mature Businesses

Trading conditions for the mature businesses have improved over the last 12 months, but nonetheless remain challenging. Revenues were up 15% to £5.74 million (2021: £4.98 million), broadly the same in each half, but pressure on margins has resulted in a small loss for the 12 months.

Current trading and outlook

Trading in the current period has started satisfactorily with order books at the mature businesses showing signs of improvement. Our primary focus remains on the opportunities we see in the construction and textile/leisure sectors where the potential graphene markets are significant and within which we are moving towards commercial product sales at the fastest rate. I look forward to reporting further progress in due course.

Neill Ricketts

Chief Executive Officer

Chief Technology Officer’s Review

The Innovate UK GSCALE programme has been running for over 18 months with the £5 million loan supporting VRS in advancing its graphene manufacturing capabilities, progressing research and development of new graphene enhanced materials, with the primary focus on commercial exploitation. This work is now largely complete and now the focus will be on monetising the technology.

We have joined the Digital Roads of the Future (DRF) Partnership which has two funding streams in place. The first being Digital Roads, an £8.6 million project sponsored by the Engineering and Physical Sciences Research Council, Costain, National Highways, the University of Cambridge; and the second being Future Roads, a £5.8 million project sponsored by 2020 Marie Skłodowska-Curie Actions COFUND (a European funding initiative), Costain and National Highways. Being a partner in this programme offers Versarien the ability to become an active player in a £14.5 million programme over five years, developing direct links to National Highways (formerly Highways England), developing stronger links with a major international Tier 1 construction company, Costain, gaining funded support for graphene material and technology development, and delivering UK wide projects with graphene materials and technologies on the road network.

We have excellent relationships with both the University of Cambridge and Costain and by using our graphene admixture for cementitious materials, CementeneTM, we can offer significant advantages to new concrete material structures including approximate 20% cost savings on ground bearing slab, reduction of CO2 emissions of up to 50%, use up to 30% less material (reduction in thickness), removal/ significant reduction in steel rebar requirements, no visible or microscopic cracking and highly workable concrete.

We are in phase 2 of a development programme for graphene-based packaging applications for a European based multi-national food products company. Similar interest is being shown by the leading global packaging and paper producer in Brazil with a development contract also now in place. The objective is to improve sustainability as well as cost effective performance.

In Spain, Gnanomat continues to upgrade its pilot plant and manufacturing capabilities as part of the INNPRESSME project. It has also signed a research contract with a global petrochemical company to evaluate the use of metal oxide/activated carbon black nanocomposites, inter alia, in active anode materials of lithium ion batteries. It is making advances in its biocide materials whilst developing prototypes for energy storage and developing new ink formulations in conjunction with Cambridge Graphene. Gnanomat materials have been utilised in the SUPPORTIVE project by 2-DTech and two supercapacitor products have been developed with associated datasheets. We are engaging with UK cell manufacturers to take forward optimised devices.

Dr Stephen Hodge

Chief Technology Officer