Versarien Plc (LON:VRS), the advanced engineering materials group, has announced its interim results for the six months ended 30 September 2020, a period in which the Company continued to progress its graphene commercialisation strategy.

Financial Highlights

· Group revenues reduced to £3.12 million (H1 2019: £4.38 million), reflecting the impact of COVID-19 on the Group’s more mature businesses

· Graphene and graphene product sales of £0.35 million (H1 2019: £0.07 million)

· Adjusted LBITDA* of £1.13 million (H1 2019: £0.57 million**)

· Reported loss before tax of £4.34 million (H1 2019: £2.14 million)

· Cash of £2.50 million at 30 September 2020 (31 March 2020: £1.66 million)

· Cash received in the period from Lanstead Sharing Agreement of £0.93 million and from Innovate UK of £1.96 million

*Adjusted LBITDA (Loss Before Interest, Tax, Depreciation and Amortisation) excludes exceptional items, share-based payment charges and other gains/losses)

** The comparative has been restated in accordance with the adoption of IFRS 16 “Leases”

Operational Highlights

· Successful launch of graphene enhanced protective face masks utilising PolygreneTM, Versarien’s graphene enhanced polymer

· Awarded £5 million Innovate UK loan with first tranche of £1.96 million received for the Company’s GSCALE project

· Project commenced with Rolls Royce and the Graphene Engineering Innovation Centre to understand and create technological advances in the aerospace sector utilising CVD graphene and other 2D materials

· Commencement of project with the Advanced Propulsion Centre for reduction of vehicle emissions

· Formation of the Versarien Graphene Advisory Panel (“VGAP”)

· Board strengthened by the appointment of James Stewart as the Company’s new independent Non-executive Chairman

GSCALE Highlights

· G – Trials ongoing to achieve capacity greater than 10 tonnes of graphene powder per annum

· S – Working with partners to develop rail carriage door side panels; phase 3 tests underway with aerospace partners

· C – GraphinksTM in concrete has demonstrated an almost 40% improvement to the compressive strength and 25% increased resistivity

· A – Infrastructure bridging solutions in course of development using knowledge gained from rail arch

· L – GrapheneWearTM base layers produced and in course of distribution for wearer trials

· E – Graphene in tyres shows a 30% increase in tyre rubber stiffness without degrading wear resistance

Post Period Highlights

· Independent report by Ankara University confirming that Versarien’s graphene materials significantly inhibit viral infection and possess anti-viral activity towards SARS-CoV-2 coronavirus

· Second generation graphene enhanced face mask prototype test results show a 99.92% anti-viral activity rate against the SARS-CoV-2 virus

· Awarded a £1.95 million development agreement by the Defence, Science and Technology Laboratory, a part of the Ministry of Defence

· Acquisition of CVD graphene assets and IP from Hanwha Aerospace Company Limited, South Korea, supported by the second Lanstead subscription and Sharing Agreement

· Award of EU Grant of €357,000 to Gnanomat for scale-up and development of electrode materials

· Appointment of Steve Hodge to the Company’s Board as Chief Technology Officer

Neill Ricketts, CEO of Versarien, commented:

“Despite the challenges posed by the COVID-19 pandemic, I am pleased with the level at which Versarien has continued to operate and particularly with the progress achieved within the graphene businesses where we have commenced the sale of our graphene enhanced face masks, as well as making further progress with a number of our collaborative projects.

“Following the launch of our face masks, we are excited that testing carried out by Ankara University has demonstrated that our hybrid graphene nanomaterials have the potential to provide protection from COVID-19 in real-world applications, including clothing and surface treatments. Prototypes for the second generation face masks have also been tested against SARS-CoV-2 and demonstrated a 99.92% resistance to the virus.

“With the acquisition of the CVD assets and IP from Hanwha Aerospace, South Korea, we now have a broad portfolio of graphene products and technologies that can service the addressable market available to us, particularly in Asia, and we intend to fully capitalise on these and other opportunities, such as our GSCALE collaborations, in the year ahead.

“In addition, we were delighted to announce the formation of the VGAP, which, thanks to the calibre of its members will play a key role in advancing our strategy to commercialise the many opportunities and applications we have. The panel will provide a platform for the debate and advancement of our graphene technology and its application both for the present and the future.

“We continue to be greatly appreciative of the support the UK Government has shown Versarien and its subsidiaries and, as such, we are proud to have provided essential supplies for the NHS and UK infrastructure at this crucial time. The employees in our businesses have been both flexible and supportive during these difficult times and it is their dedication which continues to facilitate our progress.

“Test results from the GSCALE projects have been extremely encouraging with highlights including almost 40% improvement in compressive strength in concrete and a 30% increase in tyre rubber stiffness without degrading wear resistance.

“We remain both determined and confident in meeting our objective of being the leading global graphene technology business and we look forward to making significant further commercial progress in 2021.”

Chairman’s Statement

In my first statement in the 2020 Annual Report, following my appointment in June 2020, I was pleased to highlight the progress the Company had made in the year then ended, as well as beyond, and also on its strategic focus on monetisation of the Company’s graphene technology.

In particular, reference was made to the support of the UK Government which has continued with the £1.95 million development agreement awarded in November 2020. Government support is an important pillar of our strategy as we continue to lay the foundations for our international expansion.

The acquisition of the CVD assets and IP from Hanwha Aerospace Company Limited (“Hanwha”) is an important step in ensuring that we have an appropriate portfolio of graphene products and technologies that can service the addressable market opportunities in front of us, particularly in Asia. Versarien Korea Limited has been formed as a subsidiary and will be the initial platform for commercialising opportunities in South Korea.

Our wholly owned subsidiary Beijing Versarien Technology Company Limited (“BVT”) in China has been working with the graphene mask supplier on a number of variants which are now available for supply. BVT continues to work with companies that fall within the GSCALE project such as those operating in the concrete and textile sectors.

Furthermore, I am pleased to report the Company has continued to operate all its businesses and progress its graphene commercialisation strategy in these difficult times, together with providing essential supplies for the NHS and UK infrastructure. We are utilising the UK Government furlough scheme where required, homeworking has been implemented where appropriate and those at work operate in accordance with the COVID-19 safety guidelines.

I would like to thank all our staff for their continued endeavours without which we would not have been able to make the progress that we have. Furthermore, I am delighted that Steve Hodge’s commitment has been recognised by his recent appointment to the Board as Chief Technology Officer. I am confident that we have the executive team to deliver graphene commercialisation.

James Stewart CBE

Non-executive Chairman

21 January 2021

Chief Executive Officer’s Review

Our 2020 Annual Report laid out the steps for executing our graphene commercialisation strategy including access to high quality facilities such as the University of Manchester based Graphene Engineering Innovation Centre (“GEIC”), expanding our patent portfolio, ensuring that we have appropriate investment in place and achieving commercial progress. I believe that during the period under review and more recently we have made significant advancement in these areas.

Acquisition of graphene assets and intellectual property from Hanwha

I am particularly pleased that we have, post period end, been able to close the transaction with Hanwha in South Korea to acquire its chemical vapour deposition (“CVD”) graphene assets and IP. The acquisition will provide us with access to patented technology and equipment to produce high quality single and dual layer graphene that has particular applications in the electronics sector, together with other areas, including in relation to some of our existing collaborations, particularly the project with Rolls Royce.

Based on information provided by Hanwha as part of the sale process:

· Its graphene business started in 2009 with a project to develop technologies for graphene synthesis and in 2010 the SKKU Samsung Graphene Centre was established. It succeeded in synthesising 30-inch graphene for the first time. In 2011 the South Korean Ministry of Trade, Industry and Energy (“MOTIE”) launched the Industry Source Technology Development Project (entitled “Development of transfer and continuous manufacturing technology for flexible nano film”) to build a system for processing large-scale films (500mm-level) and a pilot line was built to produce 15-inch graphene film for transparent electrodes. In 2013 prototype graphene-based touch panels were produced for cellphones.

· The same year MOTIE launched a project for the commercialisation of technology for the synthesis of ultrathin graphene layers and graphene-based flexible touch panels which was completed in 2019. The objective was to develop and commercialise graphene-based transparent electrodes for touch panels thereby substituting Indium Tin Oxide.

· In 2015, the South Korean Ministry of Science and ICT (“MSIT”) launched a project for the development of equipment and techniques for non-destructive quality evaluation of large-area graphene which was completed in September 2020.

· These and other projects have resulted in a total of over 100 patents and patent rights regarding CVD graphene in Korea, the US, China and Japan and which include synthesis, etching, transfer and application technology. Addressable markets for this technology include flexible touch panels, electrochromic heating, OLED lighting and heating films for electric vehicles.

The assets were acquired for a consideration of 11 million Versarien Ordinary Shares which at the time of issue represented a market value of £4.3 million. As part of the due diligence, the equipment was independently valued at £0.85 million with an estimated replacement cost of £2.2 million. The value of the patent portfolio continues to be assessed, both in terms of its revenue generating opportunities from development and manufacture and in terms of potential royalties from licensing agreements where blocking patents may exist.

Completion of the patent transfer process is in progress and we are evaluating premises options for the plant and equipment whilst also being in discussions locally for the establishment of operations and staffing under the umbrella of our newly formed wholly owned subsidiary incorporated in South Korea, Versarien Korea Limited.

GSCALE Project

The GSCALE (an acronym for Graphene, Seat, Concrete, Arch, Leisure, Elastomer) project, which is designed to enable Versarien to significantly increase its manufacture of quality assured graphene, is progressing and I am pleased to provide the following update:

Work Package G (Graphene)

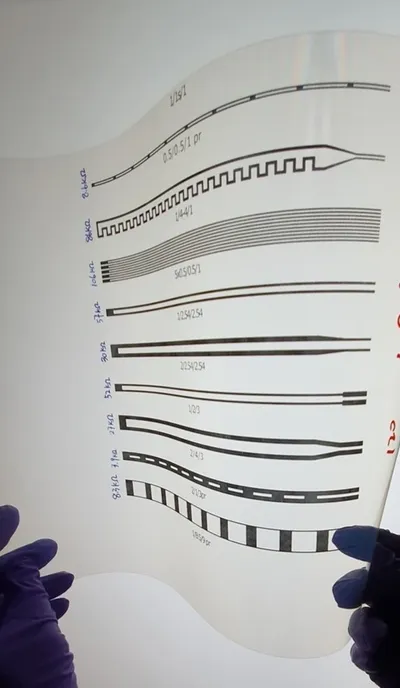

This work package will enable us to scale up capacity for production to greater than 10 tonnes of graphene powder per year. We are developing new and improved processing techniques, and developing and commissioning reliable in-process tests. For the GraphinksTM process, computational fluid dynamics (“CFD”) modelling has been performed on newly designed microchannels. Complementary experimental work has been performed using pilot scale rental homogenizers and samples are being analysed prior to a decision on system purchase.

We are in discussions with our raw material additive manufacturer regarding scale up and recycling. Trials are ongoing with our equipment manufacturer overseas to investigate graphene scale up using larger processing systems.

Our newly appointed CTO, Steve Hodge, has become Chairman of the Graphene REACH Registration Consortium Technical Working Group (TWG) and is a representative of Graphene Flagship’s ECHA-REACH Committee.

The European Chemicals Agency (ECHA) has recently accepted an updated graphene-dossier that now complies with the amended REACH regulation covering nanomaterials, introduced on 1 January 2020. Our REACH registration has also now been transferred to UK-REACH following Brexit.

Work Package S (Seat)

This work package will enable us to develop a dispersion facility at our factory in Cheltenham involving the dispersion of graphene in various thermoset systems used in fibre reinforced polymer composites.

We are working with partners to develop graphene-enhanced composites for rail interior applications, including a demonstrator for a rail carriage door side panel. Phase 3 tests are underway with aerospace supply chain partners for graphene enhanced composites.

We have continued to widen our knowledge base and have demonstrated ~5% improvement in tensile modulus of even the stiffest pitch CFRP composites. We are also looking towards bio-derived composite systems that cannot yet compete mechanically with traditional epoxy systems and have seen 20% improvements in mechanical performance using our NaneneTM in bio-prepreg based composites.

Work Package C (Concrete)

This work package involves the use of graphene in a number of construction related projects with the key objective of working towards ‘Net Zero Carbon’ targets. Graphene enhanced concrete could reduce the quantity of cement used in structures as well as the volume of aggregates and as such lead to significant CO2 footprint savings. Graphene brings improvements to the compressive strength of the material and durability, improvement to water permeability and thermal properties to improve speed of construction. These benefits could also reduce the need for expensive chemical additives or specialist material coatings.

So far, our use of GraphinksTM in concrete has demonstrated an almost 40% improvement to the compressive strength and 25% increased resistivity from the base material. A higher resistivity can help prevent electrolytic corrosion of reinforcement steel bars used in large concrete structures; combined with improved resistance to water permeability that we have also witnessed, this could significantly increase the life of the concrete and the asset. We are now working towards a number of field demonstrators in 2021 with several key partners.

We are also part of the ACORN initiative whose primary objective is to drive acceptance of a new culture in the construction industry that embraces the concept of using enough material and no more, in order to enhance sector-wide sustainability and productivity.

Work Package A (Arch)

This work package involves the use of graphene in a number of thermoplastic composite related projects. The aim is to use the knowledge gained in 3D printed graphene for various uses including technology infrastructure and footbridges.

The next step for this programme is to develop bridging solutions which will be aided by our new SME Affiliate member status with the National Composites Centre (“NCC”). The 3D printed polymer solutions (Additive Manufacturing) will focus on the rail industry safety and cost awareness by creating lightweight structures that can be installed in a safer and quicker manner, thus also reducing the time of costly line closures.

Work Package L (Leisure)

This work package covers integrating graphene into textiles, as both a coating and integrated as part of filaments and yarns.

Relating to coatings, our objective is to solidify in-house know-how on the formulations of GraphinksTM already developed, to complete ongoing tests for graphene enhanced textiles (anti-viral, anti-bacterial, anti-odour properties) for personal protective equipment (PPE) and sportswear products. We have commenced trademarking GrapheneWearTM and have a range of base-layers that were launched in late 2020, produced by MAS Innovate (Private) Limited (“MAS”), Sri Lanka. Samples will be distributed shortly to a number of end customers for testing.

Relating to textile yarns, the aim is to develop quality control/assurance procedures and the commercialisation of PolygreneTM compounds and masterbatches in a range of polymers including polypropylenes, polyesters and polyamides/nylons. So far we have achieved commercialisation of graphene face masks utilising PolygreneTM, and we have converted PolygreneTM polypropylene masterbatches to non-woven mats and chopped fibres on a pilot scale. We also have pilot scale polyester monofilament fibre-spinning trials ongoing following successful compound development in collaboration with Warwick Manufacturing Group (“WMG”).

Overall, we have solidified and extended our global supply chain partners (formulators, converters and end customers) that now includes Coats Group PLC, in addition to MAS.

Work Package E (Elastomers)

This work package aims to develop large-scale graphene-enhanced elastomer masterbatches. Initially this was for two key sectors, oil & gas and automotive tyres, but has been expanded to other sectors including shoes where we continue to develop and optimise sole formulations for a well-known end customer.

In oil & gas we have produced an 80 kg graphene/rubber masterbatch to support large scale compounding trials at a customer site in the US. In tyres, initial tests which have been undertaken indicate that we can increase the modulus (stiffness) of the tyre rubber compound by 30%. This increase in stiffness is achieved with no increase in tyre hardness which means that while rolling resistance is decreased, there is no loss of grip that would be associated with a harder tyre. If these results can be maintained or even improved at scale up, this project could lead to the production of tyres specifically aimed at the electric vehicle market.

Other Projects

The award of the product development agreement for £1.95 million by the Defence, Science and Technology Laboratory (“DSTL”), a part of the Ministry of Defence, in November 2020, demonstrates the support we are receiving from UK Government and acknowledges the quality of our products and technical ability. The agreement involves developing graphene loaded polymer composites for certain defence related applications and is due for completion by 31 March 2022.

The collaboration with Rolls Royce and the GEIC to investigate the growth of CVD grown graphene on copper wires is ongoing. The surface of copper wires is an oxide rich region, that plays no part in electrical conduction and which becomes significant as the wire gauge gets smaller and smaller. Graphene enables the copper surface to remain oxide-free after the growth process, allowing for reduced weight and higher current-carrying capacity.

Significant progress has been made optimising growth conditions for uniform multi-layer graphene on copper wires in a batch process. High temperature exposure leads to excessive oxidation of copper, however, minimal oxidation to graphene coated copper wires is observed when quantitatively assessed by Raman spectroscopy that can monitor the presence of both graphene and copper oxide peaks simultaneously. Two and four point DC resistivity measurements have shown early indications of reduced contact resistances for graphene coated copper wires, a sign that graphene could offer great potential in the design of future aircraft.

Despite the difficult US climate, we continue to work on opportunities in the US including masks, products for a leading manufacturer of premium consumer/industrial paint for coatings and tyres.

In Spain, Gnanomat has continued to make progress and has been awarded a €357,000 grant by the European Union (“EU”). This funding forms part of a total grant of over €14 million awarded to INN-PRESSME, a consortium project of which Gnanomat is a member.

Through this grant and project, Gnanomat will acquire and integrate new industrial equipment into the existing pilot plant and be involved in the development of electrode materials for supercapacitors, in collaboration with industrial partners such as CIDETEC and Skeleton Technologies, who are both involved in the development of energy storage technologies.

Additionally, Gnanomat nanomaterials are currently being tested with leading supercapacitor companies and have shown excellent functionality as a catalyst in energy storage systems such as metal/air batteries resulting in the company filing a new patent application. It has also launched a commercial channel to provide advance material products at small scale for R&D purposes.

Gnanomat’s technology has also been key to producing the graphene nanoplatelet batches doped with different metal oxide nanoparticles utilised in the testing by Ankara University to ascertain whether these materials can inactivate the SARS-CoV-2 coronavirus.

In China, work has been ongoing with our partner producing graphene enhanced face masks and we are now able to supply coloured adult masks and children’s masks. Testing of a second generation graphene enhanced face mask prototype has been conducted in China at the Analytical and Testing Centre of Capital Regions (“ATCCR”) and the test results recently received show a 99.92% anti-viral activity rate against the SARS-CoV-2 virus.

VGAP

I am delighted with the composition of the Versarien Graphene Advisory Panel (“VGAP”) which brings together some of the most eminent and knowledgeable people in the graphene sector. It is chaired by our Non-executive Director, Professor Iain Gray and includes James Baker (CEO of Graphene @Manchester), Dr. Branson Belle (senior scientist at SINTEF Norway), Professor Andrea Ferrari (Founded and directs the Cambridge Graphene Centre), Dr Kari Hjelt (The Graphene Flagships’ Head of Innovation), Professor Tony McNally (Head of Nanocomposites Research at the Warwick Manufacturing Group) and Jacqui Murray (Deputy director of the Faraday Battery Challenge).

The formation of the VGAP and the calibre of its members is key to advancing our strategy to commercialise the many opportunities and applications we have. It will also provide a platform for the debate and advancement of our graphene technology and its application both for the present and the future.

Mature businesses

The mature businesses have experienced lower revenues as a result of the pandemic, but have remained operational whilst keeping strict control of costs and using the Government furlough scheme where appropriate.

Current trading and outlook

The latest national lockdown will continue to create a challenging environment for our more mature businesses. However, the opportunities afforded by GSCALE, the DSTL development agreement and South Korean CVD graphene assets, together with the many collaboration agreements provide the opportunities to pursue our goal of graphene commercialisation both in the UK and abroad.

We remain both determined and confident in meeting our objective of being the leading global graphene technology business and we look forward to making further significant commercial progress in 2021.