Surface Transforms plc (LON:SCE) the manufacturers of carbon fibre reinforced ceramic automotive brake discs, announced today its interims results for the six months ended 30 June 2022.

Financial highlights

· Revenue increased 137% to £2.9m (H1-2021: £1.2m)

· Cash at 30 June 2022 was £6.7m (Dec 2021: £13.0m)

· Gross profit increased 129% to £1.7m (H1-2021: £0.7m)

· Administrative expenses increased 45% to £4.2m (H1-2021: £2.9m), primarily in preparation of sales growth expected in H2-2022

· Loss before tax increased to £2.5m (H1-2021: £2.2m)

· Capital expenditure on property, plant and equipment was £2.8m (H1-2021: £0.8m)

· Profit guidance maintained for full year 2022 and upgrades for 2023 to 2025

Sales and operational highlights

· Commenced series production with OEM 8, Aston Martin Valkyrie and Koenigsegg Jesko, the volume effects of which will be seen in H2-2022

· Awarded new contract with existing customer, OEM 8 having a contract value of approximately £100m, replacing the previous contract valued at £27.5m

· Additionally, post balance sheet date, announced a £13m lifetime value contract win with a new battery electric vehicle customer OEM 9

· Contracted sales order book now approximately £190m (lifetime value)

· Prospective contract pipeline (“PCP”) now approximately £400m (lifetime value) in addition to £190m contracted sales order book

· Completed phase one of the capacity installation at Knowsley bringing sales capacity to £20m p.a.

· Ordered all the equipment for phase two capacity plan that will bring total sales capacity to £50m p.a. in early 2023 thereby improving short term production resilience

· Fixed price energy contracts protect gross margin until Q2 of 2023. Thereafter significantly more efficient new furnaces reduce unit energy consumption offsetting cost increases

Outlook

The commencement of OEM 8 series monthly volumes, even if slightly later than originally planned, brings Surface Transforms into profitability for the financial year ending 31 December 2022. Assisted by higher development income, the Company was also profitable in June and July.

The financial impact of this small delay in OEM 8 start of production (“SOP”) is offset by higher than forecast development revenues with other customers. As a result, guideline profitability remains unchanged for 2022 even though sales guidance is now expected to be approximately £1.5m below previous expectations.

Moreover, looking forward to the three years 2023 to 2025, and having concluded volume discussions with OEM 8, the Board is very pleased to increase sales guidance in these years by approximately 10% p.a., almost wholly attributable to OEM 8. There are some offsetting costs – approximately £0.8m p.a. reflecting additional production overheads to support sales growth; the overall effect is to upgrade forecast profitability for 2023 to 2025.

The Company will also benefit from the super deduction scheme that will allow £15m of accelerated tax allowances, which when combined with the Company’s carry forward losses will ensure that even when profitable and based upon existing contracted values the Company will not be paying corporation tax until after 2025.

Financial Review

Revenue in the period rose 137% to £2.9m driven by increased sales to OEM customers, with a significant increase in development revenue to these same customers. In addition, steady growth to near OEM and retrofit customers boosted revenue.

Gross profit increased to £1.7m however there was deterioration of 2 percentage points in gross margin due to the higher proportion of subcontracted testing which carries a lower margin than other development income. It should be noted however that after the delivery of the 2 dynamometers the Company has on order, future testing margins for OEM customers will be closer to usual development margins. The external forces of higher energy costs had no impact on Surface Transforms as the Company has fixed price contracts that continue onto May 2023. Thereafter new furnaces due for delivery by Q1 2023 significantly reduce unit energy consumption thereby offsetting external cost increases.

Administrative costs, before research and development costs, rose 27% to £1.6m (H1-2021: £1.3m) driven in the main by salaries and increased depreciation. This was offset by a forex gain of £0.2m resulting from the decision to purchase dollars against expected furnace commitments. Research and development costs increased 59% to £2.5m (H1-2021: £1.6m), primarily driven by salaries and an increase in material usage as part of the acceptance process for new furnaces.

Planned capital expenditure of £2.8m occurred in the period being predominately payments for furnaces either under construction or delivered.

Cash at the period end was £6.7m with £3.1m held in irrevocable letters of credit. To this should be added £0.7m of an R&D tax credit received post balance sheet date. The Company remains in a net cash position of £5.5m (H1-2021: £16.9m).

Progress with potential OEM customers

OEM series production

Having won contracts in the period 2018 to 2021, the Company is now in series production with OEM 8, Aston Martin Valkyrie and Koenigsegg Jesko. Delays in SOP dates is a universal challenge across all customers. Accordingly, for our own planning we take a more prudent view on customer SOP dates. Nonetheless, when in production, we remain confident that forecast future revenue streams are de risked as volumes have historically all been in line with, or better than, guidance provided by the OEMs; a generic characteristic of the luxury car segment in which we operate. Indeed, as noted above, following our recent discussions with OEM 8, including the increase in the lifetime value of the contract, we are now increasing guidance on the Company’s expected sales through to 2025.

The next customer SOP will be with OEM 5 in Q1 2023 on a contract with a lifetime value of €11m.

OEM new contract wins

In the sales guidance of the Company, only contracts won and contracted are included as our order book. When converting these lifetime value awards to annual forecasts, the Company now includes a contingency for delays against customer SOP dates.

The Company’s contracted order book rose from £115m in December 2021 to £180m in June 2022, and approximately £190m as at the date of this statement.

In March 2022, the Company announced that it had signed a new contract with its existing customer, OEM 8 with a contract value of approximately £100m. This contract replaced the previously announced contract from September 2020, valued at approximately £27.5m. This increased contract value of over £70m was driven by both significantly increased demand for the existing model and the contract being extended to 2027.

Post balance sheet date, the Company won a £13m contract award with OEM 9. This new customer is a “disruptor” entrant to the Battery Electrical Vehicle (BEV) market.

The Company continues to expect to be able to announce at least one significant new contract in the remainder of 2022.

OEM prospective contract pipeline (“PCP”)

In this category, the Company only includes active development programmes, where there is a known model, with realistic expected volumes, a customer SOP date, engineering activity and meaningful commercial discussions. On these criteria, the PCP contains programmes with OEM 1, OEM 5, OEM 6, OEM 7, OEM 8, OEM 9, and OEM 10.

In addition to the £190m contracted order book noted above the Company has a PCP of £400m lifetime value sales; on average the contracts are now normally 5 years and typically enter production 2 years after contract win.

These prospective contracts are almost all with existing customers and are described as “carry-over” from a previously won contract onto another vehicle in the customers’ range. The prospect of winning carry-over is higher than a new product with a new customer as most of the engineering sign off has been done and generally pricing is broadly agreed. The high proportion of carry-over in our PCP gives confidence, but not certainty, of converting the pipeline into orders. The biggest risk is of course, that the programme itself gets cancelled as happened with an OEM 5 programme during the COVID pandemic, but we are protected to a certain extent against this given the number of different OEMs and models now comprising our PCP.

We are in discussions with other new customers, but it is premature to include these prospects in our planning.

Self-evidently, winning even a portion of this PCP would strain current capacity limits and the Board is therefore modelling various options in response to this issue.

OEM Business Development KPIs

As part of the process of measuring progress on the above the Company has agreed upon several business development KPIs. Using March 2021 as the comparator the KPIs show the progress that has been made by the Company up to date:

o 3 contracts in series compared with zero in March 2021

o 10 contracted models compared with 5 in March 2021

o £190m order book compared with £43m in March 2021

o 4 carry-over contracts compared with 1 in March 2021

o 5-year average contract life compared with 3.8 in March 2021

o 6 contracted OEMs compared with 4 in March 2021

o £400m PCP compared with £164m in March 2021

Retrofit and Near OEM

Retrofit sales are fitment of our discs onto already registered cars replacing either the in-situ grey iron, or not infrequently, our competitor’s carbon ceramic (“CC”) discs. Near OEM sales are to several very low volume specialist manufacturers, some of whom make less than ten cars per year. Sales into these segments have been the bedrock of Surface Transforms over the past ten years.

Whilst the segment will ultimately be dwarfed by the many times larger OEM segment, it remains important to short term profitability and cash generation. It is therefore encouraging to report that sales in the period in this segment rose to £1.3m compared with £0.8m in H1-2021.

Progress on Operations

Progress on OEM 8 production: Throughout the first half of the year the Company has progressively increased its output rate to meet the volume requirements of OEM 8, a task that has not been without its challenges but has not resulted in any abnormal launch customer situations. Now that the Company is in production the task is to get ahead of the customer’s daily needs.

Phase 2 capacity installation: The current site sales capacity is £20m p.a. We will be selling at this monthly run rate in the second half of 2022, much earlier than expected because of the increased requirements from OEM 8 and thus leaving less than planned manufacturing resilience. In February 2021 the Board anticipated the need for more 2023 capacity, albeit on lower sales projections and raised £20m to install that additional capacity – then described as Production Cell 2 – to bring total site capacity to £35m sales p.a. As a result of a new and enhanced manufacturing strategy, this second phase will now actually deliver a site sales capacity of £50m p.a. at no extra cost, reflecting both a revised site plan and a productive partnership with our furnace supplier partners. The Company has ordered all the plant required in the plan and expects completion progressively up to the first half of 2023.

This £50m p.a. sales capacity is sufficient for the expected sales in 2023 but tests resilience towards the end of the year. Thereafter, both based on expected wins from our PCP list and allowing for our need for resilience, we must plan for monthly run rate demand being more than this capacity in the next 12 to 18 months.

Cost Pressures and Cost Reductions: The significant increase in gas and electricity costs is obviously a concern for all manufacturing companies but, in combination with long standing cost reduction projects, the overall impact to Surface Transforms will be to stabilise costs rather than reduce margins. This fortunate situation arises from the fact that reducing gas and electricity consumption has been a key feature of our ESG goals over the past several years and an important element of our phase 2 capacity plan. The subsequent gas and electricity usage reduction projects are therefore now protecting margin rather than improving it. Previous guidance had not included these cost reductions benefits.

When markets return to normality, we expect these efficiencies will be manifested as cost reductions.

Progress on Environmental Social and Governance

The Company continues to extend its ESG credentials particularly on electrical vehicles (“EV”) as well as internal combustion engine vehicles (“ICE”). Weight reduction is an ever-present need for range extension on EVs whilst on ICEs the weight reduction reduces carbon emissions through lower fuel consumption. Additionally, CC discs significantly reduce brake dust particles being released into the atmosphere and watercourse, an issue of increasing interest to regulators. Finally, CC discs materially reduce the prospect of galvanic corrosion, a safety concern for grey iron discs on EVs.

However, the Company is seeking to do more than rely on our product benefits to achieve its ESG goals. In the reporting period ESG activities included:

Environment

· Regular measurement of progress against several sustainability criteria selected by the Board

· Carbon footprint reduction set as one of the key criteria in the selection of the Company’s furnace partner’s technology

· As part of our determination to be a good neighbour, the Company installed continuous emission measuring equipment that exceeds regulatory requirements

· Progress on the plan to build a Combined Heat and Power Plant

Social

· Providing well paid employment opportunities in one of the most deprived boroughs in the country

· Committing to no employee to be paid below living wage

· Continued to deepen the Company’s relationships with the local community

· Active participation in the local authority apprentice scheme

· Beginning a graduate apprentice scheme in September 2022

· Discussions with local schools and technical colleges to create partnerships and improve mutual understanding

Governance and Board Changes

· Continued the process of refreshing board membership, begun in 2021. In April 2022 the Board announced the appointment of Ian Cleminson. Ian is currently Executive Vice President and Chief Financial Officer of Innospec Inc., an international specialty chemical business employing 1900 personnel, in 23 countries with sales of over $1.5 billion and quoted on the US NASDAQ exchange with a market capitalisation of over $2 billion.

· Post balance sheet, in August 2022 Richard Gledhill announced his wish to retire with effect from October 2022. Richard has been a board member since 2009 and the Board thanks him for his considerable contribution over these years and wish him well in his well-deserved retirement.

Summary

2022 is the point at which the hard work of the past decade is being successfully converted to Company profitability. The Company is now in series production with three OEMs whilst at the same time both winning new contracts and significantly expanding the PCP. We continue to maintain profitability guidance for 2022 and are upgrading guidance for the following 3 years.

Our £190m order book is complemented by a £400m PCP. The near-term issue is capacity, whilst maintaining sufficient resilience and the Board is currently modelling options to address this.

These are exciting times for Surface Transforms.

Finally, I would like to conclude by recording the Board’s appreciation of the outstanding contribution by all members of the team. Thank You!

David Bundred

Surface Transforms Chairman

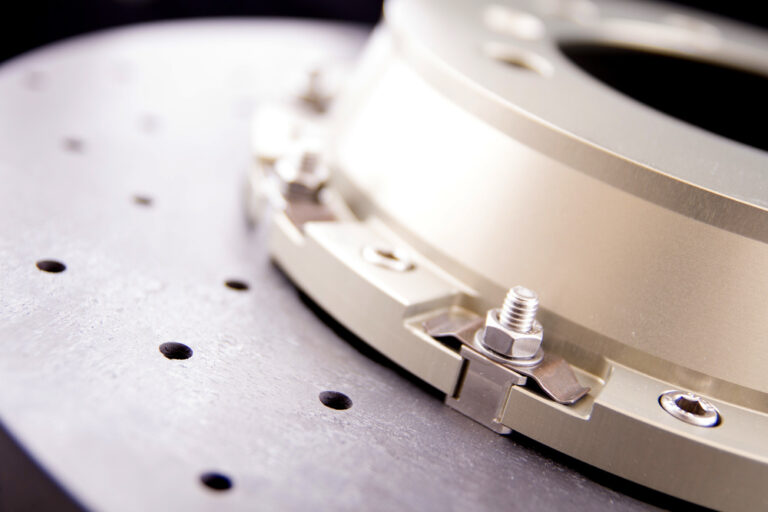

Surface Transforms plc. (LON: SCE) develop and produce carbon‐ceramic material automotive brake discs. The Company is the UK’s only manufacturer of carbon‐ceramic brake discs, and only one of two mainstream carbon ceramic brake disc companies in the world, serving customers that include major OEMs in the global automotive markets.

The Company utilises its proprietary next generation Carbon Ceramic Technology to create lightweight brake discs for high‐performance road and track applications for both internal combustion engine and electric vehicles. While competitor carbon‐ceramic brake discs use discontinuous chopped carbon fibre, Surface Transforms interweaves continuous carbon fibre to form a 3D matrix, producing a stronger and more durable product with improved heat conductivity compared to competitor products; this reduces the brake system operating temperature, resulting in lighter and longer life components with superior brake performance. These benefits are in addition to the benefits of all carbon‐ceramic brake discs vs. iron brake discs: weight savings of up to 70%, longer product life, consistent performance, reduced brake pad dust and corrosion free.