Surface Transforms (LON:SCE) manufacturers of carbon fibre reinforced ceramic automotive brake discs, has provided its unaudited interims results for the six months ended 30 June 2023 (“H1-2023”).

Financial highlights:

· Revenue increased 15% to £3.3m (H1-2022: £2.9m)

· Gross profit increased 14% to £2.0m (H1-2022: £1.7m), with margin consistent at 60%

· Operating loss1 increased to £4.6m primarily due to £2.5m of non-repeatable outlays to overcome technical challenges. Investment in teams, R&D and depreciation also increased in line with plan

· Loss before tax increased to £5.5m (H1-2022: £2.5m)

· Cash at 30 June 2023 was £4.5m (31 Dec 2022: £14.9.m)

· Improving revenue post period end, with H2-2023 revenue expected to be significantly ahead of H1-2023

1Before non-recurring items

Strategic highlights

· Revenues lower than plan due to H1 technical challenges now overcome

· Additional furnace capacity in place and increase in proprietary know how

· Strengthened leadership team for next phase of growth, including new CFO and COO

· Meeting customer demands with further OEM contract awards expected in H2-2023

· Strategic investment programme for c.£75m capacity progressing well, with capital expenditure of £4.8m (H1-2022: £2.8m). Phase 2 target of £50m capacity will be available in 2024

· Strong order book unchanged with lifetime value of contracts at £290m across 11 contracted models

· New product development for customers continues in line with the contract roadmap

· Healthy prospective contract pipeline increased to £420m (31 Dec 2022: £393m)

· Commenced planning for site expansion to c.£150m capacity

David Bundred Surface Transforms Chairman said:

“The steady growth in production seen throughout 2023 is expected to continue. Whilst H1-2023 has been operationally challenging the Company has delivered considerable strategic progress. We have engineered solutions to our technical problems and brought in additional furnace capacity designed to our know-how. Productivity efficiencies and capacity improvements are expected to continue through 2023, a target break-even in the second half of the year, with profitability in Q4.

We have continued to invest to reach, initially £50m sales capacity in 2024 and £75m sales capacity in the following year. Of greatest importance our customers have understood our issues, including immersing themselves in our capacity plans, and remain committed to awarding the Company further business. We are appreciative of shareholders support through this learning curve.”

Financial review

Revenue increased by 15% to £3.3m with approximately 75% represented by OEM customers and related development income. Near OEM customer growth has also continued and demand from retrofit customers remained strong.

Gross profit increased by 14% to £2.0m with margins remaining consistent at 60%.

Our operating loss (before non-recurring items) was £4.6 million compared to £2.4 million in the same period last year. This is due to a number of ramp-up issues we experienced as our production capacity increased to meet growing demand. These ramp-up issues resulted in lost contribution of £1.6m and costs of £0.9m with equipment failures and scrapped production. We have overcome these technical challenges and do not expect these outlays to re-occur. Indeed, the work completed has resulted in improved production processes and the design of proprietary equipment.

Administrative costs (excluding R&D) rose 52% to £2.5m driven by additional headcount and increased depreciation, combined with the actions to overcome production challenges. Research and development (“R&D”) expense increased 62% to £4.1m as new product development continues in line with the contract roadmap and the introduction of new machines and associated processes enabled those significant technical challenges to be overcome.

Non-recurring expenditures

Management have identified non-recurring items of expenditures in H1-2023, notably £0.5m of unprecedented energy costs from a one -off period of being subject to a variable rate in H1-2023. The Company has fixed energy costs until March 2024. A further £0.3m of one-off restructuring costs as ramp up demanded temporary skills sets during this transition.

After taking into account higher administrative, R&D costs, the £2.5m one off costs associated with ramp up challenges as well as the £0.9m of non-recurring expenditures the Company reports a loss before tax of £5.5 million in H1-2023, compared to a loss of £2.5 million in H1-2022.

Capital expenditure and cash

Planned capital expenditure of £4.8 million occurred in the period, primarily aimed at delivering 2024 capacity, with full year capex now expected to be in the region of £8m. This extra capacity will provide resilience during the continuing ramp up in the second half of 2023 and also underpins the projected further near doubling of sales in 2024. In addition, the Company’s manufacturing capacity expansion programme remains on track to deliver capacity equivalent to £75 million in 2025.

Cash at the end of the period was £4.5 million, down £10.4 million from the year-end. This was due to revenue loss whilst overcoming ramp up challenges in H1 and continued capital investments for 2024. Prudent cash management along with a re-phasing of capital expenditure on the next phase of capacity expansion has minimised the impact of one-off costs incurred resolving the technical problems and delayed production ramp up. Accordingly, year-end cash is expected to be within £1m of previous management estimates.

Commercial progress:

Satisfying immediate customer demand whilst investing in capacity and manufacturing resilience for strategic growth remains the Board’s over-riding priority.

Despite the production challenges in H1-2023, the Company is addressing demand in H2-2023 for current in-series production. Whilst we have experienced delays in shipping product owing to the ramp-up challenges earlier this year, we have worked closely with our customers throughout and are broadly meeting their requirements.

Our contracted order book has risen in line with expectations, from approximately £180 million to £290 million. Our prospective contract pipeline is now approximately £420 million. Near OEMs and Retrofit customers remain a valued and steady income stream.

We currently have model contracts with 6 OEM manufacturers and remain in discussions with other OEMs. Furthermore, and despite the technical problems incurred in the period, our OEM customers have been fully supportive and the Board expect to be awarded further OEM contracts in H2-2023.

Operational progress

The technical problems incurred in Q1 constrained our production and sales. These challenges were resolved in Q2 and the Company has been increasing production rates ever since. Q3 is showing steady progress, and the company expects to continue ramping up its growth in Q4.

Supply chain challenges have caused production delays, impacting customers and some capital investments, however we have developed alternatives to minimise the risk.

Looking ahead to 2024, the Company’s strategic focus is on:

o Installed capacity: capable of meeting demand and building inventory headroom;

o Increasing capacity: expanding production capacity the focus is now on phase 2 which is expected to come on stream in 2024;

o Advancing our plans for site expansion to scale up capacity to £150 million;

o Site infrastructure: investing in new facilities and equipment to support growth;

o Building talent and capability: attracting and retaining top talent to support the Company’s growth; and

o Maintaining margin: identifying opportunities to reduce inefficiency to improve.

People

It is a pleasure to welcome Isabelle Maddock who joins as Chief Financial Officer and Board Director after a 9- year tenure as CFO with James Cropper PLC. It is also a pleasure to welcome Stephen Easton to the team as (non-Board) Chief Operating Officer, Stephen has joined after a 16-year tenure with SGL Carbon. Both these senior appointments strengthen an already dynamic team focused on delivering the manufacturing expansion and financial transformation of the Company.

To support talent programmes, we work with key universities and local colleges to secure a number of individuals on apprenticeships and graduate programmes. These programmes help us to attract and retain top talent, develop future leaders, reduce training costs, improve productivity, and boost morale. Since the start of the year, we have taken in three apprentices and have also secured nine graduates primarily in IT, Engineering, Manufacturing Technology, Human Resources, Finance and Sales roles. Approximately 26% of the current workforce are graduates.

We continue to be an employer of choice in the area offering well paid employment opportunities and excellent prospects within a growing and inclusive environment.

Environment

Brake dust is a major source of air pollution, and it is becoming an increasingly talked-about problem. There are more vehicles on the road than ever before, and newer models tend to have more powerful and bigger brakes. Our carbon ceramic brake discs significantly reduce brake pad wear and hence brake pad dust emissions compared to traditional brake discs. They are also lighter, last longer, do not corrode and cope better with high accelerating, heavy vehicles, making them well-suited for electric vehicles (EVs) that require brakes which are used less frequently, but need higher energy braking performance, weight reduction and lower brake pad dust emissions. Our research team is collaborating with innovative automotive suppliers to develop new brake disc technologies that can further reduce brake dust emissions and improve the performance of EV’s.

Reducing manufacturing energy and carbon footprint is a top priority for the Company. All capital investments made this year and for future furnaces and power plants are continually assessed based on their potential to reduce energy and carbon costs.

Outlook

The steady growth in production seen throughout 2023 is expected to continue. Whilst H1-2023 has been operationally challenging the Company has delivered considerable strategic progress. We have engineered a solution to our technical problems and brought in additional furnace capacity designed to our know-how. Productivity efficiencies and capacity improvements are expected to continue through 2023, a target break-even in the second half of the year, with profitability in Q4.

We have continued to invest to reach, initially £50m sales capacity in 2024 and £75m sales capacity in the following year. Of greatest importance our customers have understood our issues, including immersing themselves in our capacity plans, and remain committed to awarding the Company further business. We are appreciative of shareholders support through this learning curve.

| Statement of total comprehensive income | |||

| For the 6 months ended 30 June 2023 | Six months ended | Six months ended | Year ended |

| 30-Jun-23 | 30-Jun-22 | 31-Dec-22 | |

| Unaudited | Unaudited | Audited | |

| £’000 | £’000 | £’000 | |

| Revenue | 3,282 | 2,857 | 5,121 |

| Cost of Sales | (1,323) | (1,143) | (2,039) |

| Gross Profit | 1,958 | 1,714 | 3,082 |

| Other Income | 7 | 24 | 36 |

| Administrative Expenses: | |||

| Before research and development costs | (2,475) | (1,626) | (3,365) |

| Research and development costs | (4,125) | (2,549) | (5,625) |

| Total administrative expenses | (6,600) | (4,175) | (8,990) |

| Operating loss before non-recurring items | (4,636) | (2,437) | (5,872) |

| Non-recurring items | (763) | – | – |

| Financial Income | 2 | 1 | 6 |

| Financial Expenses | (87) | (82) | (180) |

| Loss before tax | (5,484) | (2,519) | (6,046) |

| Taxation | 643 | 348 | 1,264 |

| Loss for the year after tax | (4,840) | (2,171) | (4,782) |

| Total comprehensive loss for the year attributable to members | (4,840) | (2,171) | (4,782) |

| Loss per ordinary share | |||

| Basic and diluted | (2.01)p | (1.11)p | (2.34)p |

| Statement of financial position | As at | As at | As at |

| As at 30 June 2023 | 30-Jun-23 | 30-Jun-22 | 31-Dec-22 |

| £’000 | £’000 | £’000 | |

| Unaudited | Unaudited | Audited | |

| Non-current assets | |||

| Property, plant and equipment | 18,864 | 11,325 | 15,188 |

| Intangibles | 3,412 | 1,018 | 2,237 |

| 22,277 | 12,343 | 17,425 | |

| Current assets | |||

| Inventories | 4,023 | 2,315 | 3,376 |

| Trade and other receivables | 1,970 | 987 | 1,051 |

| Other receivables | 3,086 | 2,403 | 3,400 |

| Current asset investment | – | 3,007 | – |

| Cash and cash equivalents | 4,506 | 3,712 | 14,924 |

| 13,585 | 12,424 | 22,750 | |

| Total assets | 35,862 | 24,767 | 40,175 |

| Current liabilities | |||

| Other interest-bearing loans and borrowings | (211) | (211) | (211) |

| Lease liabilities | (348) | (299) | (295) |

| Trade and other payables | (4,058) | (2,765) | (3,710) |

| (4,617) | (3,274) | (4,216) | |

| Non-current liabilities | |||

| Government grants | (181) | (194) | (188) |

| Lease liabilities | (1,290) | (1,402) | (1,335) |

| Other interest-bearing loans and borrowings | (783) | (1,054) | (887) |

| Total liabilities | (6,872) | (5,925) | (6,626) |

| Net assets | 28,990 | 18,842 | 33,551 |

| Equity | |||

| Share capital | 2,417 | 1,954 | 2,406 |

| Share premium | 58,375 | 41,469 | 58,215 |

| Capital reserve | 464 | 464 | 464 |

| Retained loss | (32,266) | (25,044) | (27,534) |

| Total equity attributable to equity shareholders of the Company | 28,990 | 18,842 | 33,551 |

| Statement of Cash Flows | ||||||

| for the 6 months ended 30 June 2023 | ||||||

| Six months ended | Six months ended | Year ended | ||||

| 30-Jun-23 | 30-Jun-22 | 31-Dec-22 | ||||

| Unaudited | Unaudited | Audited | ||||

| £’000 | £’000 | £’000 | ||||

| Cash flow from operating activities | ||||||

| Loss after tax for the year | (4,840) | (2,171) | (4,782) | |||

| Adjusted for: | ||||||

| Depreciation and amortisation charge | 591 | 441 | 969 | |||

| Equity settled share-based payment expenses | 108 | 95 | 216 | |||

| Foreign exchange losses/(gains) | 43 | (210) | (345) | |||

| Financial expense | 87 | 82 | 180 | |||

| Financial income | (2) | (1) | (6) | |||

| Non-government grant amortisation | – | – | (12) | |||

| Taxation | (643) | (348) | (1,264) | |||

| Changes in working capital | (4,656) | (2,112) | (5,044) | |||

| Decrease/(increase) in inventories | (647) | (977) | (2,038) | |||

| Decrease/(increase) in trade and other receivables | (1,135) | (951) | (1,805) | |||

| Increase/(decrease) in trade and other payables | (80) | 775 | 1,720 | |||

| (6,518) | (3,265) | (7,167) | ||||

| Taxation received | 1,172 | – | 709 | |||

| Net cash used in operating activities | (5,346) | (3,265) | (6,458) | |||

| Cash flows from investing activities | ||||||

| Acquisition of tangible and intangible assets | (4,839) | (2,751) | (8,351) | |||

| Cash transfer (to)/from current asset investments | – | – | 3,007 | |||

| Interest received | 2 | – | 6 | |||

| Net cash used in investing activities | (4,838) | (2,751) | (5,337) | |||

| Cash flows from financing activities | ||||||

| Proceeds from issue of share capital, net of expenses | 171 | 24 | 18,051 | |||

| Cost for issue of share capital | – | – | (828) | |||

| Payment of finance lease liabilities | (85) | (80) | (153) | |||

| Proceeds from long term loans | – | – | – | |||

| Payments of long term loans | (191) | (303) | (473) | |||

| Interest paid | (87) | (82) | (180) | |||

| Net cash generated from financing activities | (192) | (441) | 16,417 | |||

| Net (decrease)/increase in cash and cash equivalents | (10,375) | (6,457) | 4,620 | |||

| Foreign Exchange losses | (43) | 210 | 345 | |||

| Cash and cash equivalents at the beginning of the period | 14,924 | 12,966 | 9,959 | |||

| Cash and cash equivalents at the end of the period | 4,506 | 6,719 | 14,924 | |||

| Statement of changes in equity | |||||

| For the six months ended 30 June 2023 | |||||

| Share capital | Share premium account | Capital reserve | Retained loss | Total | |

| £’000 | £’000 | £’000 | £’000 | £’000 | |

| Balance as at 31 December 2022 | 2,406 | 58,215 | 464 | (27,534) | 33,551 |

| Comprehensive income for the period | |||||

| Loss for the period | – | – | – | (4,840) | (4,840) |

| Total comprehensive income for the period | – | – | – | (4,840) | (4,840) |

| Transactions with owners, recorded directly to equity | |||||

| Share options exercised | 11 | 160 | – | – | 171 |

| Equity settled share based payment transactions | – | – | – | 108 | 108 |

| Total contributions by and distributions to the owners | 11 | 160 | – | 108 | 279 |

| Balance at 30 June 2023 | 2,417 | 58,375 | 464 | (32,266) | 28,990 |

Notes

1. Accounting policies

The interim financial statements are the responsibility of the Directors and were authorised and approved by the Board of Directors for issuance on 27 September 2023.

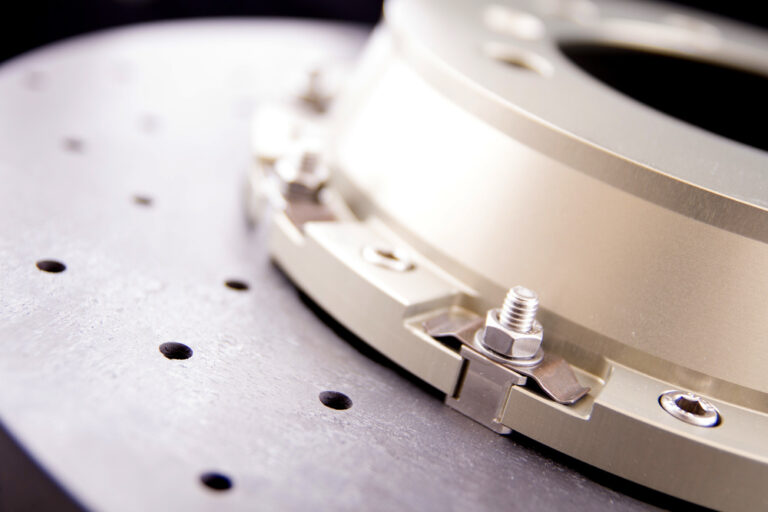

About Surface Transforms

Surface Transforms plc. (LON:SCE) develops and produces carbon‐ceramic material automotive brake discs. The Company is the UK’s only manufacturer of carbon‐ceramic brake discs, and only one of two mainstream carbon ceramic brake disc companies in the world, serving customers that include major OEMs in the global automotive markets.

The Company utilises its proprietary next generation Carbon Ceramic Technology to create lightweight brake discs for high‐performance road and track applications for both internal combustion engine cars and electric vehicles. While competitor carbon‐ceramic brake discs use discontinuous chopped carbon fibre, Surface Transforms interweaves continuous carbon fibre to form a 3D matrix, producing a stronger and more durable product with improved heat conductivity compared to competitor products; this reduces the brake system operating temperature, resulting in lighter and longer life components with superior brake performance. These benefits are in addition to the benefits of all carbon‐ceramic brake discs vs. iron brake discs: weight savings of up to 70%, longer product life, consistent performance, reduced brake pad dust and corrosion free.

The Company holds the London Stock Exchange’s Green Economy Mark.

For additional information please visit www.surfacetransforms.com