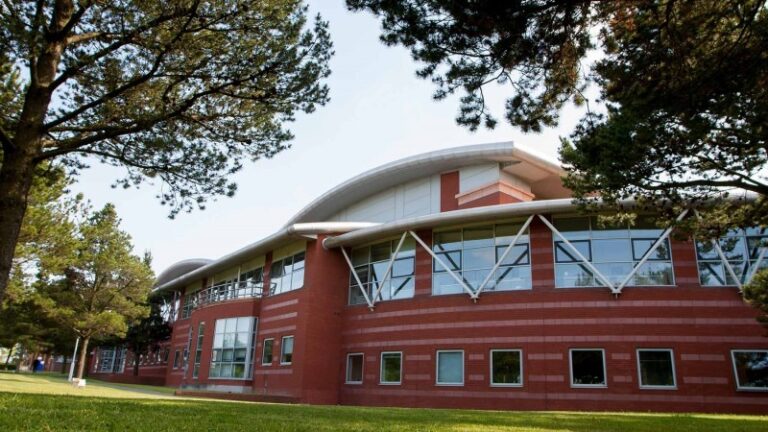

PowerHouse Energy Group plc (LON:PHE), the UK technology company pioneering hydrogen production from waste plastic and end-of-life tyres, is pleased to provide an update on progress with the demonstration system at the University of Chester’s Thornton Science Park.

The DMG® (Distributed Modular Gasification) demonstration system was successfully commissioned last summer after a complete rebuild and upgrade on its arrival in the UK. The system has continued to operate as expected over a period of nearly six months with a variety of feedstocks producing high-quality synthesis gas (“syngas”) safely and efficiently. Independent engineering analysis of the gas produced by tyre crumb has determined that the syngas can be adequately purified to provide a 99.999% pure stream of road-fuel-quality hydrogen while in parallel generating electricity from excess syngas.

Thus far in 2018, the testing program at the Thornton site has been concentrated on plastics – our initial targeted commercial feedstock. Both native plastic and waste plastic feedstock have been tested under a variety of pre-determined conditions to produce hydrogen-rich syngas and syngas for electrical generation.

The penultimate aim of the testing program has been the successful operation of the Company’s gas generator system for the production of electricity. The gas generator set has been operated on the syngas streams derived from each native and waste plastic using the syngas produced by the DMG® system for internal load operations. The data derived from this testing program is contributing substantially to the front-end-design engineering program for our first commercial project targeted at the Ellesmere Port area as announced previously. Subsequent to initial commercial operations the Company will finalise the engineering of the ultimate aim of the DMG® System: hydrogen production.

The next stage of electrical production testing for the DMG® system will include connection of the generator to the Energy Centre’s micro-grid at Thornton Science Park. The site engineering for the micro-grid connection is under way and is being managed by the Energy Centre, with the expectation that the PowerHouse system will support the operation of the centre’s combined heating and power plant and other independently operated electrical components.

David Ryan, Technical Director of PowerHouse Energy Group plc, commented: “The results of the plastics testing have been very encouraging and allow us to feed valuable data into our rapidly advancing commercial process design. We continue to use the data derived from our process demonstration unit in our ongoing dialogue with prospective manufacturers and to aid and accelerate our planning and permitting processes.”