2021 was a landmark year for the CT Automotive Group (LON:CTA), as we successfully navigated a challenging market backdrop, while completing our AIM listing in December and achieving record sales.

Scott McKenzie Chief Executive Officer

Introduction

The automotive industry has historically been demand-led and hence the just-in-time production processes facilitated the alignment of production schedules with raw materials and parts orders. The pandemic and related lockdowns have caused supply-side issues which re-shaped the global automotive market in 2021 and look set to continue through at least the first half of 2022. With the pressure to build-back by OEMs around the world mounting, and supply chain

issues easing to a degree, the industry is set for a significant bounceback.

Operations – production trading

The supply chain issues in 2021, most notably the shortages of semiconductors, caused significant volatility for OEM. This resulted in a number of customer temporary shutdowns (for example, two weeks without production) and also reduced output across the industry.

Global light vehicle production amounted to 73.4 million vehicles in 2021, up only 3.8% on 2020. So far in 2022, there have been some pandemic-related lockdowns in China, however these have been restricted to certain areas, primarily Shanghai, and hence our operations have not seen any significant disruptions other than resourcing activities which have been completed quickly to ensure continuity of supply.

The Group optimised operations through 2020 and 2021 to better deal with the unpredictable customer production

schedules. However, in line with the experience of manufacturers across the global automotive sector, the ‘stop-start’

production impacted efficiency and created some additional quality costs.

Customer schedules, although still at reduced levels, have started to become more consistent and reliable in Q1 2022, with reduced in-month order cancellations. Such cancellations were most disruptive in Q3 2021, with in-month order reductions running at c.37%. This improved slightly in Q4 2021 to c.27% and has further improved to c.17% in Q1 2022, as expected. There were numerous headwinds impacting light vehicle production across the industry in Q3 2021, most notably the semiconductor shortages and disrupted shipping schedules. These shipping schedules in 2022 have become noticeably more stable.

The nature of our production cycle relies on customer schedules being upheld. This is particularly important for production completed in China and then shipped to the UK, US and Europe. In 2021, there was an increased level of in-month order cancellations due to customer supply chain issues. As a result, this caused issues with overstocking certain product lines in our UK and US distribution centres. In 2022, this has improved as noted above, and hence our stock levels are more balanced across the Group and our various locations.

37% >27%>17%

Q3>Q4>Q1

SEVERE SUPPLY CHAIN-RELATED DISRUPTION WITH IN-MONTH ORDER CANCELLATIONS RUNNING AT 20-25% VS A NORMAL LEVEL OF C.1%

UPDATED FIGURES FOR THIS SHOWSIMPROVEMENT IN 2022

Operations – production tooling

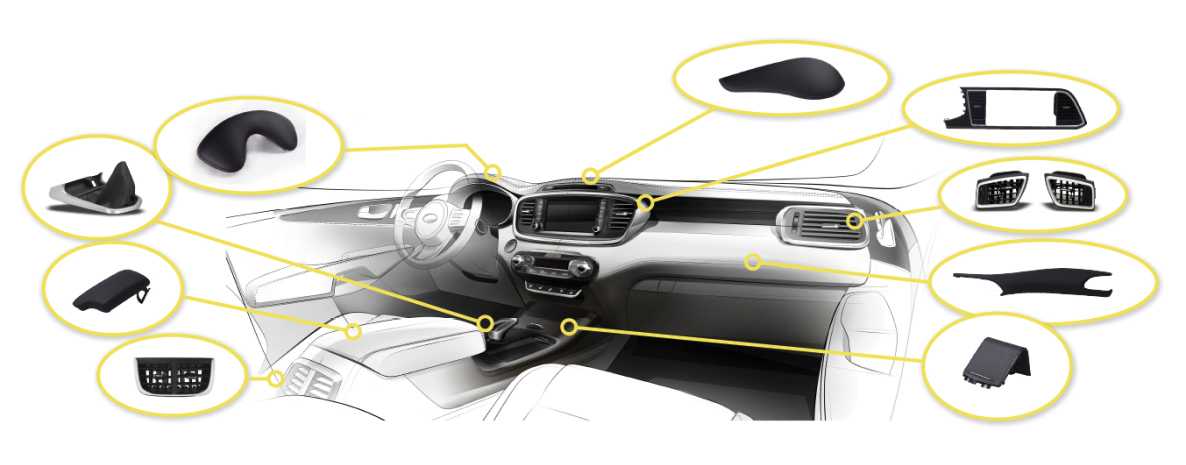

Our in-house toolroom in Shenzhen had a very busy year, running at maximum capacity on new programmes for a variety of products. We are particularly pleased as this reflects the efforts made to increase utilisation of our in-house

tooling capabilities, rather than outsourcing. Development has been broadly isolated from supply chain issues in 2021, and progress has been able to largely continue irrespective of customer shutdowns. The main impact has been a small number of delayed vehicle launches causing minor delays to tooling approvals.

Agility

Agility is one of our core values and has been more important than ever through the last two years. As a high-growth business, there are always multiple challenges and fast changes impacting the business. Our people have adopted a culture to: Assess, Adjust, Act – allowing us to respond appropriately to challenges as they arise.

There are many examples of this agility over the last two years, most notably in our working practices, including how many of our people have transitioned to working from home, and how we have maintained strong communication and relationships with significantly reduced travel (previously a key element in our global business).

This agility is crucial as we continue to adapt to capitalise on market trends, such as EVs, or design trends, such as hidden IP vents, or addressing the impact of tax changes such as the US S301 tariffs.

Expanding in the EV sector

Our design expertise and track record has allowed us to maintain our market position as a supplier for EVs. This can be seen in our customer mix and the vehicles we are nominated on which include both established EV manufacturers and new entrants to the markets. This is supported by our recent nominations on EV cars, including the Nissan Ariya and e.Go Mobile.

The growth in EVs is also driving an increase in the potential value of interior components that the Group can supply per model. In addition, technology advances in autonomous driving have been most prevalent across EVs, resulting in more ‘hands-off’ time and interaction with a vehicle’s interior. EV marques, including Lucid and a major global EV OEM, have focused particular attention on their vehicles’ interior design, with the Group’s highest value of supplied components per vehicle being that within the new Lucid Air.

The trend towards EVs continues to gain momentum across the globe. This has been further enhanced in 2021 with the multiple commitments from OEMs towards full electrification (largely following the COP 26 event in November 2021). We have also seen a trend of customers prioritising EV production lines when chip availability has been restricted. Within the automotive sector, EV sales reached 6.75 million globally in 2021, up 108% on 2020.

Trading performance in Q3 and Q4 2021 was challenging due to the supply chain conditions, and reflected by the global light vehicle production, however we attribute our slight overall outperformance of the global market to the Group’s significant exposure to EVs. The Group has above average exposure to the EV segment, with 17% of revenue

derived from EV platforms, compared to EVs overall market share by volume of 8%.

Setting up new plant in Puebla, Mexico

Following the introduction of additional import tariffs by the Trump administration on certain goods arriving from China into the USA, it has become less economical for the Group to supply components to US-based customers

directly from China. While the Group has entered into cost sharing agreements with some of its existing customers to mitigate the impact of the tariffs, the Directors do not believe that they would be able to competitively bid for new contracts supplied directly by the Group’s Chinese plants while the tariffs remain in force.

In order to continue to supply to customers, including a major EV company in the US without the imposition of the China Tariffs, the Group is setting up a new manufacturing site in Mexico from which it will export to the US. The plant has been identified with a new lease signed and a number of new staff on site from May 2022. This site has in place the

required infrastructure, including appropriate energy connections, to allow the Group to rapidly deploy machinery. Industrialisation of the plant, including shipping the tools from China, will proceed across May and July with production on track to start in H2 2022.

CT has developed a low-cost modular factory design (inclusive of fixtures, quality gauges and capital equipment), with production lines to be built and tested in China prior to shipment, resulting in substantial reductions in capital expenditure. The Directors estimate that capital expenditure of c.$2.5 million will be required to prepare the site for first production. The Group has followed a demand-led expansion program and has secured contracts for delivery from the Mexico plant such that it is expected to be revenue generating immediately upon completion. This new site will allow us to remain competitive, and expand, in the North American market without tariffs, and continues to be well received by our customers.

Outlook

The semiconductor shortages have continued to impact the industry in early 2022, with further short-term disruption also caused by the Ukraine invasion in Europe. Our customer schedules are however becoming more consistent which allows the Group to more effectively plan production schedules and better manage stock levels across the globe. We continue to expect a recovery in global production across 2022, most significantly in H2 2022, as supply issues ease. This recovery timing is largely aligned with public statements made by a number of OEMs and Tier One suppliers.

The current customer trend towards prioritising key models, due to chip restrictions, is leading to EVs and larger

models typically being favoured. Although our mix of programmes is powertrain agnostic and includes a mixture of model sizes, this trend typically favours CT with our above- average exposure to EV compared to the market. This is aligned with the existing direction of travel of continued increased demand for EVs and the commitments towards achieving full electrification on new models made by a number of OEMs. As a result of existing nominations, we anticipate the Group to benefit from increased serial production revenues in 2022 as the OEMs seek to meet the pent-

up consumer demand for cars, with the full effect of new launches in 2021 contributing to further growth for CT. Accordingly, we have seen production volumes start to recover in early 2022, and expect this to continue ahead of automotive supply chain issues resolving fully in 2023.

The Group is positioned to recover strongly, with c.97% of anticipated revenue in 2022 and c.91% of anticipated revenue in 2023 expected to come from projects which are currently underway or on which the CT Automotive Group is already the nominated supplier. This will be further supported once the new plant in Mexico is operational, allowing us to be more competitive in the North American markets.

Scott McKenzie

Chief Executive Officer