BSF Enterprise plc (LON:BSFA) Managing Director Dr Che Connon caught-up with DirectorsTalk for an exclusive interview on how its subsidiary Lab-Grown Leather is transforming the traditional leather market. It’s high-quality, sustainable and versatile ‘leather’ alternative is receiving plaudits from some of the world’s luxury fashion houses.

Q1. Che, artificial leather has been promoted as a more sustainable alternative to traditional leather. But is it truly fulfilling its promise?

A1. There are still environmental concerns remaining around artificial leather. However, going back to traditional leather or ‘slaughtered’ leather, if you want to be more emotive, there’s obviously the animal welfare issue. And then there’s the processing of tanning compounds which is also involved. I think it’s fair to say that the majority of tanneries especially under EU Directive have improved a lot in terms of the chemicals they use: they’re moving away from glutaraldehydes and from metals such as chromium in the tanning process. So there’s been good progress in terms of addressing some of the environmental aspects of the tanning of traditional animal skins, but of course the source is still animals.

At present, it’s still up for debate whether leather is a byproduct or co-product of the meat industry. It’s certainly not a waste product. But nonetheless, I think it is clear that if you didn’t have leather from animal, that would have a positive impact on animal welfare.

What’s been happening over the last ten or so years is a movement away from leather into alternatives. Now initially those alternatives were just driven by price, so cheap alternatives to leather, for example PVC and different types of plastics. These were derived from oil and things like that and are therefore dependent upon the Petrochemical industry. How do they break down? They don’t break down! And this creates all sorts of environmental issues for the world.

Now more recently, there’s been moves to improve some of these artificial materials, and I think it’s be fair to say to reduce the amount of petrochemical-sourced materials in them. Some may be looking to replace them fully. So, the trend is to reduce the amount of plastics in alternative leathers and replace plastics with other materials fully.

There’s two kind of approaches. Most leather alternatives are still using some form of plastic in there, albeit reduced, to minimise cost and improve the material’s strength. We also have alternative materials. These plant-based or fungal-based materials (e.g. mushrooms) are typically produced and made very, very thin. So they need to be bulked up with something else and that could be or can be some of the more plastic derived materials. So you’re reducing the amount of plastic – but not by very much – but you are improving the feel, or texture, of the material. However, the overall impact on the environment is not that great.

Some of the other materials looking to replace those plastic elements have the problem that they are just not durable enough. They don’t meet the requirements in terms of the strength and handling ability and very restrictive in their colour palettes, dying and things like that. So they’re not proving to be very popular.

Q2. What approach have you taken at Lab-Grown leather?

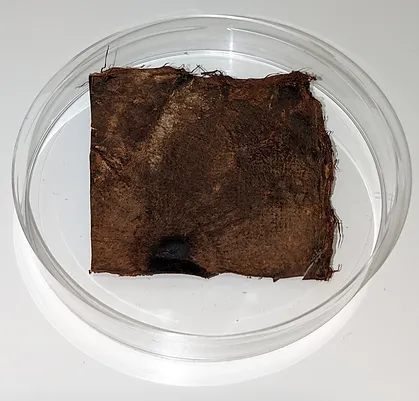

A2. We are taking a very different approach that is both unique and innovative. We are the only company in the world with 100% naturally structured lab-grown leather.

We are taking all of the good things about leather, obviously putting aside the animal welfare issues. The fact that it’s a usable material, it’s strong, it has a texture and feel that we like and appreciate. Customers are also used to appreciating the way that leather wears, the patternation and its ageing which reflects in the beauty of the product. So there’s all these different things about leather that we, the customer, like and the key is to replicate those in the corneal alternatives by creating the same structure.

The reason why leather behaves the way it does is because of its ultrastructure; the molecular components – the nanoscale arrangement of proteins in the skin that forms the leather. If you replicate that correctly then everything else falls into place and that’s what we’re able to do at Lab-Grown Leather.

We’ve been able to use the technology developed initially within 3D Bio-Tissues (3DBT) that has been transferred into Lab-Grown Leather and we’ve been able to produce the skin with all of that ultrastructural elements remaining or being the same. The result is the final leather product is ‘leather’ and it behaves exactly the same way and has similar strengths, if not stronger.

It wears, folds and feels exactly like leather because it’s made of the same material that Leather is made of. It’s just that it didn’t involve the killing of an animal and importantly, it doesn’t use any plastics in the manufacturing process. It doesn’t need to be backed on to anything because again, it has its own inner strength and thickness in the same way that leather does.

Q3. Are there any other advantages you’d like to mention?

A3. By controlling the removal of animals from the process, we can design the structure of the skin for tanning and make it a simpler tanning process. We can actually design in elements, which means the processes are cheaper and more environmentally friendly further down the tanning line. The structure not only provides the durability in the finish and feel but also versatility. If you can control the size and shape of the skin, then you can make much larger pieces whilst maintaining the high-quality consistency, which is crucial for high-end leather goods.

In contrast, at the moment, because the leather coming out is a natural product, it has to be assessed and not one piece is the same as another piece, which is a major problem when people are using it to manufacture very expensive items.

Q4. Have you had any feedback from any fashion groups? A4. Yes, we’ve had feedback from one of the leading fashion houses that they said our Lab-Grown leather was ‘world class’ and the ‘best alternative material’ they’ve ever seen. Conversations with other fashion brands have highlighted that the alternatives don’t currently meet their expectations. We certainly believe that’s the case, and we think that this approach is really going to solve a lot of the issues not just in terms of the animal impact, but also avoiding the uses of other materials like plastics in the production of the current alternatives.

BSF Enterprise plc is a UK-based investment company that primarily focuses on biotechnology, particularly in the field of tissue engineering and synthetic biology. The company aims to invest in businesses that are working on cutting-edge biological solutions, especially in areas like sustainable food production, health, and clean technology. The core focus of BSF Enterprise is on developing commercially viable products that harness biological advancements.

One of its most notable projects is 3D Bio-Tissues (3DBT), a subsidiary that specialises in cell-based tissue engineering. This technology has applications in producing lab-grown meat, which is seen as a potential sustainable alternative to traditional animal farming. The goal is to create scalable, ethical, and environmentally friendly solutions to meet the growing demand for protein.

BSF Enterprise plc is listed on the London Stock Exchange (LSE) under the ticker BSFA. Its investments and operations reflect a strong emphasis on sustainability and reducing environmental impact while advancing biotechnological innovation.