Anglo American Plc (LON:AAL), today announced Preliminary Results for the year ended 31 December 2018.

Consistent performance improvements deliver 4% increase in underlying EBITDA to $9.2 billion

Mark Cutifani, Chief Executive of Anglo American, said: “We are delivering improvements on a consistent basis, with a further 4% increase in underlying EBITDA to $9.2 billion. Our commitment to disciplined capital allocation has helped strengthen our balance sheet by more than $10 billion over three years, with net debt reduced to $2.8 billion at the end of 2018. This strong financial result derives from our continued productivity improvements in the underlying operations and better than expected prices for many of our products.

“No degree of financial performance is worth a life, however, and in 2018, five of our colleagues tragically died in workplace safety incidents. The safety of our people is always front of mind and our determination to reach and sustain zero harm is our most pressing challenge.

“Our focus on efficiency and productivity, including through our Operating Model implementation, is continuing to deliver benefits – in terms of both safety and financial returns. In 2018, we produced 10% more product on a copper equivalent basis from half the number of assets we had in 2012. As a result, our productivity(1) per employee has doubled, supporting a 12 percentage point increase in mining margin(2) to 42% and placing us amongst the leaders in the industry. Over that six-year period, we have delivered $4.6 billion of annual underlying EBITDA improvement in terms of costs and volumes, including $0.4 billion in 2018. Looking forward, we see significant further potential and by 2022, we are targeting an additional $3-4 billion annual underlying EBITDA run-rate improvement, relative to 2017.

“Anglo American is a resilient and highly competitive business with a clear asset-led strategy. What’s more, our world-class portfolio benefits from considerable organic growth options, particularly in those products that will supply a cleaner, more electrified world and that satisfy the consumer-led demands of a fast growing global middle-class. Our focus is on unlocking the very significant additional potential that we see within the business – from further productivity improvements, volume growth from existing and new operations, and the deployment of FutureSmart Mining™ technologies – and to do so safely and responsibly, maintaining strict capital discipline and creating a sustainable business in every sense.”

Financial highlights – year ended 31 December 2018

· Generated underlying EBITDA* of $9.2 billion, a 4% increase, and $3.2 billion of attributable free cash flow*

· Delivered profit attributable to equity shareholders of $3.5 billion, a 12% increase

· Reduced net debt* to $2.8 billion, a 37% reduction since 2017 – 0.3x net debt / underlying EBITDA

· Achieved net cost and volume improvements of $0.4 billion(3)

· Expected 2019 cost and volume improvements of $0.5 billion, and on track to deliver $3-4 billion annual EBITDA improvement by 2022, relative to 2017

· Proposed final dividend of $0.51 per share, equal to 40% of second half underlying earnings*

|

Year ended US$ million, unless otherwise stated |

31 December 2018 |

31 December 2017 |

Change |

|

Revenue |

27,610 |

26,243 |

5% |

|

Underlying EBITDA* |

9,161 |

8,823 |

4% |

|

Underlying earnings* |

3,237 |

3,272 |

(1)% |

|

Attributable free cash flow* |

3,157 |

4,943 |

(36)% |

|

Profit attributable to equity shareholders of the Company |

3,549 |

3,166 |

12% |

|

Underlying earnings per share* ($) |

2.55 |

2.57 |

(1)% |

|

Earnings per share ($) |

2.80 |

2.48 |

13% |

|

Dividend per share ($) |

1.00 |

1.02 |

(2)% |

|

Group attributable ROCE* |

19% |

19% |

– |

SUSTAINABILITY PERFORMANCE

Safety

Anglo American’s safety performance is the subject of very significant management attention in order to eliminate the causes of harm in the workplace. Five people lost their lives in 2018, all in South Africa, two in each of our Platinum Group Metals (PGMs) and Coal businesses and one in our Diamonds business. As a matter of urgency, we launched an Elimination of Fatalities Taskforce during 2018 to further interrogate drivers of fatal incidents at a more granular, cultural level, to understand how we can better manage fatal and catastrophic risks. Our determination to deliver our commitment to zero harm is our most pressing challenge.

The Group’s total recordable case frequency rate for the year provides a broader picture of significant progress, with 2.66 injuries per million hours worked, a 16% improvement over the record performance rate achieved in 2017. However, we should not be experiencing major safety incidents and we have demonstrated time and again that even our most potentially hazardous businesses can be incident-free for long periods.

Environment

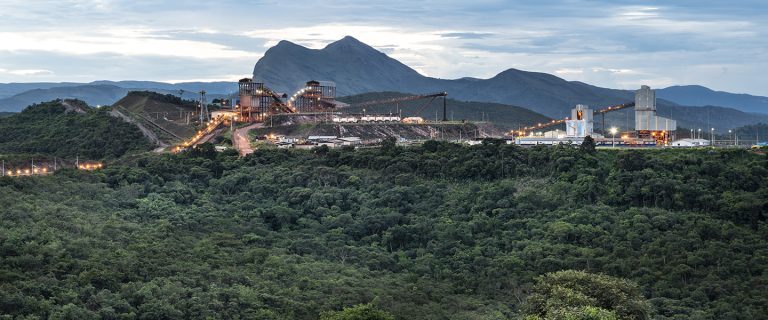

We recorded one Level 4 and five Level 3 environmental incidents in 2018. The most serious related to two leakages of non-hazardous iron ore slurry from Minas-Rio’s pipeline in Brazil. Both leaks were stopped without delay, without injuries and a thorough clean-up of the surrounding area was completed. We also took a responsible approach to the inspection and repair of the pipeline, pre-emptively replacing a number of sections.

Our sustainability goals include our commitment to be a leader in environmental stewardship. By 2030, we aim to: reduce GHG emissions by 30% against a 2016 baseline and improve energy efficiency by 30%; achieve a 50% net reduction in freshwater abstraction in water-scarce regions; and deliver net-positive impacts in biodiversity wherever we operate. We are also working on ensuring all operations fully align with our Biodiversity Standard and our best-in-class Integrated Mine Closure Planning System. Currently, 12% of our energy needs are met by renewables, and we are working to increase this.

Tailings

We manage our tailings dams with the utmost care and have full confidence in the integrity of our 56 managed tailings storage facilities around the world. We are, of course, following developments carefully to ensure any learnings from recent tragic events are integrated into our own processes and controls. There is nothing we have seen to date to cause us to alter our already stringent approach to tailings dam safety management.

We have a mandatory Group Technical Standard for tailings dam safety management which exceeds regulatory requirements. We conduct daily and fortnightly inspections, with quarterly external audits performed by specialised consulting firms. There are also annual inspections performed by the Engineer of Record (who is external to Anglo American) who are themselves also subject to independent, external reviews. These processes are in addition to the various forms of remote and other monitoring technologies installed at appropriate sites that measure everything from ground movement to temperature and hydrology, as examples.

Sustainable mining

Our far-reaching Sustainable Mining Plan, launched in 2018 as part of the FutureSmart Mining™ programme, commits us to a series of ambitious medium and longer terms goals. These relate to three major areas of sustainability aligned to the UN’s 2030 Sustainable Development Goals: trusted corporate leader (i.e. advocating for the highest standards of governance to drive transparency and trust in mining and mined products); healthy environment; and thriving communities. While our environmental goals will rely on many of the technologies we are beginning to deploy, we are also thinking innovatively to create regional ecosystems of sustainable economic activity, in partnership with appropriate development experts.

Anglo American has a long track record as a leader in sustainable, responsible mining. Such attributes were recognised in April 2018 in the inaugural Responsible Mining Index, across all metrics and particularly in relation to economic development, community wellbeing and lifecycle management.

(1) Productivity indexed to 2012 benchmark.

(2) The mining margin represents the Group’s underlying EBITDA margin for the mining business. It excludes the impact of PGMs purchase of concentrate, third-party purchases made by De Beers, third-party trading activities performed by Marketing, the Eskom-tied South African domestic thermal coal business and reflects Debswana accounting treatment as a 50/50 joint venture.

(3) Excludes the impact of the suspension of operations at Minas-Rio.

Operational and financial review of Group results for the year ended

31 December 2018

OPERATIONAL PERFORMANCE

We have continued to improve the performance of our assets through increased efficiency and productivity, including the implementation of our Operating Model and, as a result, have delivered $0.4 billion of cost and volume improvements in 2018 ($0.8 billion excluding above CPI increases in oil and other energy costs, and rail constraints at Kumba). Across the Group, production increased by 6% on a copper equivalent basis, excluding the impact of the stoppage at Minas-Rio, primarily driven by continued strong performances at Copper, Metallurgical Coal and De Beers, as well as improved production at our PGMs business. This was partly offset by curtailed production at Kumba Iron Ore as a result of third-party rail constraints.

Copper production increased by 15% to 668,300 tonnes (2017: 579,300 tonnes), with increases at all operations. Collahuasi delivered record copper in concentrate production, benefiting from a strong plant performance following the completion of planned plant improvement initiatives and planned higher ore grades. At Los Bronces, production increased by 20%, owing to strong mine and plant performance, as well as planned higher ore grades.

Metallurgical coal production increased by 11% to 21.8 Mt (2017: 19.7 Mt), driven by a record performance from Moranbah and production growth at Grosvenor.

De Beers’ rough diamond production increased by 6% to 35.3 million carats (2017: 33.5 million carats). Production increases at Orapa and the contribution from the ramp-up of Gahcho Kué more than offset the effect of the temporary suspension of production at Venetia following a fatal incident and the placing of Voorspoed mine onto care and maintenance.

At our PGMs business, platinum production increased by 4% to 2,484,700 ounces (2017: 2,397,400 ounces) and palladium by 3% to 1,610,800 ounces (2017: 1,557,400 ounces), reflecting continued strong performance at Mogalakwena and ongoing operational improvements at Amandelbult. Refined platinum production decreased by 4% to 2,402,400 ounces (2017: 2,511,900 ounces) and refined palladium by 10% to 1,501,800 ounces (2017: 1,668,500 ounces) as scheduled smelter maintenance delayed refined production into 2019.

At Kumba, iron ore output decreased by 4% to 43.1 Mt (2017: 45.0 Mt) due to Transnet’s rail performance constraints throughout 2018. In response, Kumba took the strategic decision to improve product quality to maximise the value of those tonnes railed to the port, which in turn reduced total production.

At Thermal Coal – South Africa, total export production decreased by 1% to 18.4 Mt (2017: 18.6 Mt), as operations continued to transition between mining areas.

Nickel production decreased by 3% to 42,300 tonnes (2017: 43,800 tonnes) owing to a 40-day planned maintenance stoppage at Barro Alto. Manganese ore production increased by 3% to 3.6 Mt (2017: 3.5 Mt), reflecting improved concentrator availability and favourable weather conditions at the Australian operations.

Group copper equivalent unit costs were in line with the prior year in both local currency and US dollar terms as the effect of cost and productivity initiatives offset the impact of inflation across the Group. A 9% decrease in unit costs at Copper, owing to increased production and continued cost savings across all the operations, was offset by Metallurgical Coal, where increased costs were incurred to establish new mining areas to achieve further productivity improvements, and at Kumba following lower production and higher strip ratios.

Excluded from the Group copper equivalent result is the impact of Minas-Rio suspending operations from March 2018, following the two pipeline leaks. The operations resumed after the receipt of the appropriate regulatory approvals on 20 December, following an extensive and detailed technical inspection and the precautionary replacement of certain sections of the pipeline. In addition, on 21 December, a key regulatory approval relating to the Minas-Rio Step 3 licence area was granted, providing greater operational flexibility and access to higher grade iron ore to support the increase of production towards the full design capacity of 26.5 million tonnes per year.

FINANCIAL PERFORMANCE

Anglo American’s profit attributable to equity shareholders increased to $3.5 billion (2017: $3.2 billion). Underlying earnings were $3.2 billion (2017: $3.3 billion), while operating profit was $6.1 billion (2017: $5.5 billion).